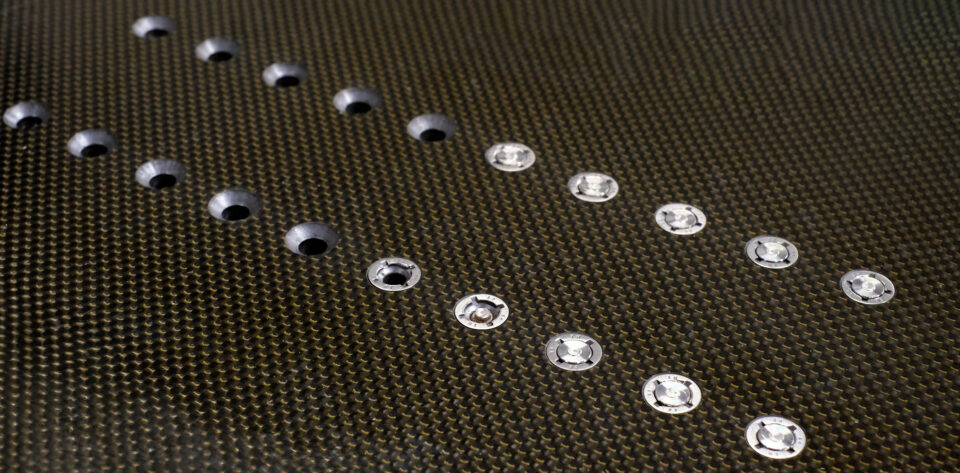

Eddie-Bolts® represent a cutting-edge aerospace fastening system, specifically designed for composite structures. These fasteners feature a unique pin and nut configuration, providing exceptional clamping power and reliability in demanding aerospace applications. Eddie-Bolts are manufactured using high-quality materials to ensure superior performance and durability. These materials include various alloys and finishes, tailored to meet the stringent requirements of aerospace engineering.

Each Eddie-Bolt® consists of a pin with flutes in the upper portion of its threaded area and a corresponding nut. When the nut is torqued, it deforms into the flutes of the pin, thereby creating a mechanical lock. This interaction also produces a consistent and reliable clamping load that is distributed evenly across the joint, enhancing the joint’s overall stability and integrity. The mechanical lock provides exceptional resistance to vibrations, a necessary feature in dynamic environments like aerospace, where fasteners are routinely subjected to high levels of stress. This allows them to maintain their integrity and tightness without regular maintenance or re-tightening. Their robust design and reliable performance make them a preferred choice for many critical aerospace assemblies.

Key Features of Eddie-Bolts:

- High Clamping Power: Eddie-Bolts are known for their exceptional clamping power, which ensures a tight and secure fastening.

- Free-Running Nut: The system includes a free-running nut that simplifies the installation process, allowing the nut to be threaded onto the bolt without resistance until the clamping load is achieved.

- Positive Mechanical Lock: During installation, the nut engages with flutes on the bolt, forming a positive mechanical lock that prevents the bolt from loosening due to vibrations or other forces.

Standard Eddie-Bolt® Removal Methods:

Traditionally, Eddie-Bolts® are removed using standard methods such as drilling or grinding. While effective, these methods can be time-consuming and may pose risks to surrounding structures. Additionally, standard removal techniques may generate debris or foreign object debris (FOD), impacting safety and reliability.

Removing an Eddie Bolt, particularly from the head side, involves a process that can be carefully managed with tools like a drill, appropriate drill bits, and a punch. Here’s a step-by-step guide on how to do this:

Step-by-Step Guide to Remove an Eddie-Bolt®:

Setup: Select the Right Drill Bit and punch. Choose a drill bit that matches the diameter of the Eddie-Bolt’s® shank. This is crucial to ensure that you remove enough of the bolt without damaging the surrounding material.

- Center Punch:

- Place a center punch on the head of th Eddie-Bolt® and give it a firm tap with a hammer. This creates a starting point for the drill and prevents it from wandering when you begin drilling.

- Drilling Out the Bolt:

- Position the drill at the punch mark. Start the drill at a low speed to establish a groove and gradually increase the speed as you go deeper. Drill down to just above where the threads start in the receiving material, not through the entire length of the bolt to avoid damaging the threads or the material beyond.

- Removing the Bolt Head:

- Once the top part of the bolt is sufficiently drilled through, use a chisel and hammer or a punch to gently tap around the edges of the bolt head. This can help in breaking it free from the shank. Alternatively, if the head does not come off easily, you may need to drill a bit deeper.

- Extracting the Shank:

- After the head is removed, the remaining shank may still be lodged within the material. Use a suitable punch that fits into the hole left by the removed bolt head. Carefully tap the punch with a hammer to push the shank through the material. Ensure that you support the backside of the material to prevent any bending or damage from the impact.

- Clean and Inspect:

- After removal, inspect the hole and surrounding area for any damage. Clean out any metal shavings or debris. If the hole is to be reused, check for thread integrity and make sure it’s free from obstructions.

Safety and Tips:

- Always wear appropriate personal protective equipment such as safety goggles and gloves when drilling and hammering.

- Ensure that the workpiece is securely fastened and stable.

- Use cutting fluid or oil when drilling metals to reduce heat and wear on the drill bit.

- If the bolt is particularly resistant, consider applying heat around the bolt head to expand the metal slightly, making it easier to break the head free.

Removing Eddie-Bolts® Using E-Drill: Simplified, Safe, and Efficient

E-Drill presents a superior solution for removing Eddie-Bolts®. Unlike traditional methods, E-Drill utilizes advanced Electrical Discharge Machining (EDM) Technology, minimizing the risk of damage to surrounding structures and reducing the likelihood of generating debris. E-Drill’s precision and efficiency make it an ideal choice for aerospace maintenance and repair tasks, ensuring safe and reliable fastener removal with minimal disruption.

Setup

Select the fastener to be removed from the drop-down menu in the fastener library. Ensure the correct electrode is installed, and choose the appropriate locator (e.g., Button Head or Vacuum Flush Head Locator).

If you haven’t programmed the machine to remove Eddie-Bolts yet, use the “Build Fastener” screen to input the necessary data. Gather the relevant properties from the manufacturer’s fastener drawings, which are usually easy to find online. You’ll need information such as head type (flush or protruding), radius, head height, head angle (for flush fasteners), and shank diameter.

Input this data into the Touch Screen Display (TSD), which will recommend the correct electrode and locator tool. Once the fastener is configured, it will be saved in the fastener library for future use. For detailed instructions on how to build a fastener on the E-Drill system, visit this E-Drill Acadcemy Page on identifying and building fasteners.

Step 1: Locate

Position the Button Head Bushing or Flush Head Vacuum locator precisely over the Eddie-bolt’s® head. It’s crucial to align the locator concentrically around the fastener to ensure accuracy. Once in position, insert the hand tool and apply gentle pressure, enough to seal the rubber O-Ring around the fastener head.

Step 2: Cut

Activate the E-Drill by squeezing the trigger and hold until the display light indicates the status of the cut. This process will usually take between 7-12 seconds depending on the fasteners shank diameter and material.

Step 3: Punch

The final step involves using a punch that matches the size of the electrode used for the cut. Align the punch with the cut ring of the fastener and apply a moderate force before pulling the trigger. The shank of the fastener will then be severed from the fastener head, leaving a clean and empty hole. The precise and clean cut from the E-Drill usually ensures that the bolt can be removed with minimal effort.

Advantages of Using E-Drill for Eddie-Bolt® Removal:

- Speed: The E-Drill significantly speeds up the removal process compared to traditional drilling methods, saving time and money.

- Safety for Technicians: E-Drill’s method eliminates the need for intense physical handling and exposure to sharp remnants or heavy equipment, making it a safer option for technicians.

- Aircraft Structural Integrity: The precision of the E-Drill minimizes the risk of accidental damage to surrounding structures, preserving the integrity of the aircraft.

- No FOD or Debris: Unlike drilling, the E-Drill flushes the cut with water and vacuums out all debris, eliminating the risk of foreign object debris (FOD) that could compromise aircraft safety and operation.

By adopting the E-Drill for Eddie-Bolt® removal, maintenance teams can achieve a more efficient, safer, and cleaner operation, aligning with the best practices in aerospace maintenance.

Eddie-Bolt® Part Numbers:

| Part Number | Head Style | Material | Nominal Diameter |

|---|---|---|---|

| EL1202EN5-( ) | 100° Reduced Flush Shear | 6Al-4V Titanium | 5/32 in |

| EL1202EN6-( ) | 100° Reduced Flush Shear | 6Al-4V Titanium | 3/16 in |

| EL1202EN8-( ) | 100° Reduced Flush Shear | 6Al-4V Titanium | 1/4 in |

| EL1202EN10-( ) | 100° Reduced Flush Shear | 6Al-4V Titanium | 5/16 in |

| EL1202EN12-( ) | 100° Reduced Flush Shear | 6Al-4V Titanium | 3/8 in |

| EL1202EN5-(X) | 100° Reduced Flush Shear | 6Al-4V Titanium | 5/32 in |

| EL1202EN6-(X) | 100° Reduced Flush Shear | 6Al-4V Titanium | 3/16 in |

| EL1202EN8-(X) | 100° Reduced Flush Shear | 6Al-4V Titanium | 1/4 in |

| EL1202EN10-(X) | 100° Reduced Flush Shear | 6Al-4V Titanium | 5/16 in |

| EL1202EN12-(X) | 100° Reduced Flush Shear | 6Al-4V Titanium | 3/8 in |

| EL1202EN6-(Y) | 100° Reduced Flush Shear | 6Al-4V Titanium | 3/16 in |

| EL1202EN8-(Y) | 100° Reduced Flush Shear | 6Al-4V Titanium | 1/4 in |

| EL1202EN10-(Y) | 100° Reduced Flush Shear | 6Al-4V Titanium | 5/16 in |

| EL1202EN12-(Y) | 100° Reduced Flush Shear | 6Al-4V Titanium | 3/8 in |

| EL1202EN5-(S) | 100° Reduced Flush Shear | 6Al-4V Titanium | 5/32 in |

| EL1202EN6-(S) | 100° Reduced Flush Shear | 6Al-4V Titanium | 3/16 in |

| EL1202EN8-(S) | 100° Reduced Flush Shear | 6Al-4V Titanium | 1/4 in |

| EL1202EN10-(S) | 100° Reduced Flush Shear | 6Al-4V Titanium | 5/16 in |

| EL1202EN12-(S) | 100° Reduced Flush Shear | 6Al-4V Titanium | 3/8 in |

| EL1202EN5-(XS) | 100° Reduced Flush Shear | 6Al-4V Titanium | 5/32 in |

| EL1202EN6-(XS) | 100° Reduced Flush Shear | 6Al-4V Titanium | 3/16 in |

| EL1202EN8-(XS) | 100° Reduced Flush Shear | 6Al-4V Titanium | 1/4 in |

| EL1202EN10-(XS) | 100° Reduced Flush Shear | 6Al-4V Titanium | 5/16 in |

| EL1202EN12-(XS) | 100° Reduced Flush Shear | 6Al-4V Titanium | 3/8 in |

| EL1202EN6-(YS) | 100° Reduced Flush Shear | 6Al-4V Titanium | 3/16 in |

| EL1202EN8-(YS) | 100° Reduced Flush Shear | 6Al-4V Titanium | 1/4 in |

| EL1202EN10-(YS) | 100° Reduced Flush Shear | 6Al-4V Titanium | 5/16 in |

| EL1202EN12-(YS) | 100° Reduced Flush Shear | 6Al-4V Titanium | 3/8 in |

| EL2201NC5-( ) | Protruding Shear | 6Al-4V Titanium | 5/32 in |

| EL2201NC6-( ) | Protruding Shear | 6Al-4V Titanium | 3/16 in |

| EL2201NC8-( ) | Protruding Shear | 6Al-4V Titanium | 1/4 in |

| EL2201NC10-( ) | Protruding Shear | 6Al-4V Titanium | 5/16 in |

| EL2201NC12-( ) | Protruding Shear | 6Al-4V Titanium | 3/8 in |

| EL2201NF5-( ) | Protruding Shear | 6Al-4V Titanium | 5/32 in |

| EL2201NF6-( ) | Protruding Shear | 6Al-4V Titanium | 3/16 in |

| EL2201NF8-( ) | Protruding Shear | 6Al-4V Titanium | 1/4 in |

| EL2201NF10-( ) | Protruding Shear | 6Al-4V Titanium | 5/16 in |

| EL2201NF12-( ) | Protruding Shear | 6Al-4V Titanium | 3/8 in |

| EL2201NC5-(X) | Protruding Shear | 6Al-4V Titanium | 5/32 in |

| EL2201NC6-(X) | Protruding Shear | 6Al-4V Titanium | 3/16 in |

| EL2201NC8-(X) | Protruding Shear | 6Al-4V Titanium | 1/4 in |

| EL2201NC10-(X) | Protruding Shear | 6Al-4V Titanium | 5/16 in |

| EL2201NC12-(X) | Protruding Shear | 6Al-4V Titanium | 3/8 in |

| EL2201NF5-(X) | Protruding Shear | 6Al-4V Titanium | 5/32 in |

| EL2201NF6-(X) | Protruding Shear | 6Al-4V Titanium | 3/16 in |

| EL2201NF8-(X) | Protruding Shear | 6Al-4V Titanium | 1/4 in |

| EL2201NF10-(X) | Protruding Shear | 6Al-4V Titanium | 5/16 in |

| EL2201NF12-(X) | Protruding Shear | 6Al-4V Titanium | 3/8 in |

| EL2201NC6-(Y) | Protruding Shear | 6Al-4V Titanium | 3/16 in |

| EL2201NC8-(Y) | Protruding Shear | 6Al-4V Titanium | 1/4 in |

| EL2201NC10-(Y) | Protruding Shear | 6Al-4V Titanium | 5/16 in |

| EL2201NC12-(Y) | Protruding Shear | 6Al-4V Titanium | 3/8 in |

| EL2201NF6-(Y) | Protruding Shear | 6Al-4V Titanium | 3/16 in |

| EL2201NF8-(Y) | Protruding Shear | 6Al-4V Titanium | 1/4 in |

| EL2201NF10-(Y) | Protruding Shear | 6Al-4V Titanium | 5/16 in |

| EL2201NF12-(Y) | Protruding Shear | 6Al-4V Titanium | 3/8 in |

| EL3202EN5-( ) | 100° Flush Tension | 6Al-4V Titanium | 5/32 in |

| EL3202EN6-( ) | 100° Flush Tension | 6Al-4V Titanium | 3/16 in |

| EL3202EN8-( ) | 100° Flush Tension | 6Al-4V Titanium | 1/4 in |

| EL3202EN10-( ) | 100° Flush Tension | 6Al-4V Titanium | 5/16 in |

| EL3202EN12-( ) | 100° Flush Tension | 6Al-4V Titanium | 3/8 in |

| EL3202EN5-(X) | 100° Flush Tension | 6Al-4V Titanium | 5/32 in |

| EL3202EN6-(X) | 100° Flush Tension | 6Al-4V Titanium | 3/16 in |

| EL3202EN8-(X) | 100° Flush Tension | 6Al-4V Titanium | 1/4 in |

| EL3202EN10-(X) | 100° Flush Tension | 6Al-4V Titanium | 5/16 in |

| EL3202EN12-(X) | 100° Flush Tension | 6Al-4V Titanium | 3/8 in |

| EL3202EN6-(Y) | 100° Flush Tension | 6Al-4V Titanium | 3/16 in |

| EL3202EN8-(Y) | 100° Flush Tension | 6Al-4V Titanium | 1/4 in |

| EL3202EN10-(Y) | 100° Flush Tension | 6Al-4V Titanium | 5/16 in |

| EL3202EN12-(Y) | 100° Flush Tension | 6Al-4V Titanium | 3/8 in |

| EL3202EN5-(S) | 100° Flush Tension | 6Al-4V Titanium | 5/32 in |

| EL3202EN6-(S) | 100° Flush Tension | 6Al-4V Titanium | 3/16 in |

| EL3202EN8-(S) | 100° Flush Tension | 6Al-4V Titanium | 1/4 in |

| EL3202EN10-(S) | 100° Flush Tension | 6Al-4V Titanium | 5/16 in |

| EL3202EN12-(S) | 100° Flush Tension | 6Al-4V Titanium | 3/8 in |

| EL3202EN5-(XS) | 100° Flush Tension | 6Al-4V Titanium | 5/32 in |

| EL3202EN6-(XS) | 100° Flush Tension | 6Al-4V Titanium | 3/16 in |

| EL3202EN8-(XS) | 100° Flush Tension | 6Al-4V Titanium | 1/4 in |

| EL3202EN10-(XS) | 100° Flush Tension | 6Al-4V Titanium | 5/16 in |

| EL3202EN12-(XS) | 100° Flush Tension | 6Al-4V Titanium | 3/8 in |

| EL3202EN6-(YS) | 100° Flush Tension | 6Al-4V Titanium | 3/16 in |

| EL3202EN8-(YS) | 100° Flush Tension | 6Al-4V Titanium | 1/4 in |

| EL3202EN10-(YS) | 100° Flush Tension | 6Al-4V Titanium | 5/16 in |

| EL3202EN12-(YS) | 100° Flush Tension | 6Al-4V Titanium | 3/8 in |

| EL3202EN8-(B) | 100° Flush Tension | 6Al-4V Titanium | 1/4 in |

| EL3202EN10-(B) | 100° Flush Tension | 6Al-4V Titanium | 5/16 in |

| EL3202EN8-(XB) | 100° Flush Tension | 6Al-4V Titanium | 1/4 in |

| EL3202EN10-(XB) | 100° Flush Tension | 6Al-4V Titanium | 5/16 in |

| EL3202EN8-(YB) | 100° Flush Tension | 6Al-4V Titanium | 1/4 in |

| EL3202EN10-(YB) | 100° Flush Tension | 6Al-4V Titanium | 5/16 in |

| EL4202EN5-( ) | Protruding Tension | 6Al-4V Titanium | 5/32 in |

| EL4202EN6-( ) | Protruding Tension | 6Al-4V Titanium | 3/16 in |

| EL4202EN8-( ) | Protruding Tension | 6Al-4V Titanium | 1/4 in |

| EL4202EN10-( ) | Protruding Tension | 6Al-4V Titanium | 5/16 in |

| EL4202EN12-( ) | Protruding Tension | 6Al-4V Titanium | 3/8 in |

| EL4202EN5-(X) | Protruding Tension | 6Al-4V Titanium | 5/32 in |

| EL4202EN6-(X) | Protruding Tension | 6Al-4V Titanium | 3/16 in |

| EL4202EN8-(X) | Protruding Tension | 6Al-4V Titanium | 1/4 in |

| EL4202EN10-(X) | Protruding Tension | 6Al-4V Titanium | 5/16 in |

| EL4202EN12-(X) | Protruding Tension | 6Al-4V Titanium | 3/8 in |

| EL4202EN6-(Y) | Protruding Tension | 6Al-4V Titanium | 3/16 in |

| EL4202EN8-(Y) | Protruding Tension | 6Al-4V Titanium | 1/4 in |

| EL4202EN10-(Y) | Protruding Tension | 6Al-4V Titanium | 5/16 in |

| EL4202EN12-(Y) | Protruding Tension | 6Al-4V Titanium | 3/8 in |

| EL4202EN5-(S) | Protruding Tension | 6Al-4V Titanium | 5/32 in |

| EL4202EN6-(S) | Protruding Tension | 6Al-4V Titanium | 3/16 in |

| EL4202EN8-(S) | Protruding Tension | 6Al-4V Titanium | 1/4 in |

| EL4202EN10-(S) | Protruding Tension | 6Al-4V Titanium | 5/16 in |

| EL4202EN12-(S) | Protruding Tension | 6Al-4V Titanium | 3/8 in |

| EL4202EN5-(XS) | Protruding Tension | 6Al-4V Titanium | 5/32 in |

| EL4202EN6-(XS) | Protruding Tension | 6Al-4V Titanium | 3/16 in |

| EL4202EN8-(XS) | Protruding Tension | 6Al-4V Titanium | 1/4 in |

| EL4202EN10-(XS) | Protruding Tension | 6Al-4V Titanium | 5/16 in |

| EL4202EN12-(XS) | Protruding Tension | 6Al-4V Titanium | 3/8 in |

| EL4202EN6-(YS) | Protruding Tension | 6Al-4V Titanium | 3/16 in |

| EL4202EN8-(YS) | Protruding Tension | 6Al-4V Titanium | 1/4 in |

| EL4202EN10-(YS) | Protruding Tension | 6Al-4V Titanium | 5/16 in |

| EL4202EN12-(YS) | Protruding Tension | 6Al-4V Titanium | 3/8 in |

| ELS120NF5-( ) | 100° Reduced Flush Shear | 6Al-4V Titanium | 5/32 in |

| ELS120NF6-( ) | 100° Reduced Flush Shear | 6Al-4V Titanium | 3/16 in |

| ELS120NF8-( ) | 100° Reduced Flush Shear | 6Al-4V Titanium | 1/4 in |

| ELS120NF10-( ) | 100° Reduced Flush Shear | 6Al-4V Titanium | 5/16 in |

| ELS120NF12-( ) | 100° Reduced Flush Shear | 6Al-4V Titanium | 3/8 in |

| ELS120NN5-( ) | 100° Reduced Flush Shear | 6Al-4V Titanium | 5/32 in |

| ELS120NN6-( ) | 100° Reduced Flush Shear | 6Al-4V Titanium | 3/16 in |

| ELS120NN8-( ) | 100° Reduced Flush Shear | 6Al-4V Titanium | 1/4 in |

| ELS120NN10-( ) | 100° Reduced Flush Shear | 6Al-4V Titanium | 5/16 in |

| ELS120NN12-( ) | 100° Reduced Flush Shear | 6Al-4V Titanium | 3/8 in |

| ELS120NC5-( ) | 100° Reduced Flush Shear | 6Al-4V Titanium | 5/32 in |

| ELS120NC6-( ) | 100° Reduced Flush Shear | 6Al-4V Titanium | 3/16 in |

| ELS120NC8-( ) | 100° Reduced Flush Shear | 6Al-4V Titanium | 1/4 in |

| ELS120NC10-( ) | 100° Reduced Flush Shear | 6Al-4V Titanium | 5/16 in |

| ELS120NC12-( ) | 100° Reduced Flush Shear | 6Al-4V Titanium | 3/8 in |

| ELS120NF5-(X) | 100° Reduced Flush Shear | 6Al-4V Titanium | 5/32 in |

| ELS120NF6-(X) | 100° Reduced Flush Shear | 6Al-4V Titanium | 3/16 in |

| ELS120NF8-(X) | 100° Reduced Flush Shear | 6Al-4V Titanium | 1/4 in |

| ELS120NF10-(X) | 100° Reduced Flush Shear | 6Al-4V Titanium | 5/16 in |

| ELS120NF12-(X) | 100° Reduced Flush Shear | 6Al-4V Titanium | 3/8 in |

| ELS120NN5-(X) | 100° Reduced Flush Shear | 6Al-4V Titanium | 5/32 in |

| ELS120NN6-(X) | 100° Reduced Flush Shear | 6Al-4V Titanium | 3/16 in |

| ELS120NN8-(X) | 100° Reduced Flush Shear | 6Al-4V Titanium | 1/4 in |

| ELS120NN10-(X) | 100° Reduced Flush Shear | 6Al-4V Titanium | 5/16 in |

| ELS120NN12-(X) | 100° Reduced Flush Shear | 6Al-4V Titanium | 3/8 in |

| ELS120NC5-(X) | 100° Reduced Flush Shear | 6Al-4V Titanium | 5/32 in |

| ELS120NC6-(X) | 100° Reduced Flush Shear | 6Al-4V Titanium | 3/16 in |

| ELS120NC8-(X) | 100° Reduced Flush Shear | 6Al-4V Titanium | 1/4 in |

| ELS120NC10-(X) | 100° Reduced Flush Shear | 6Al-4V Titanium | 5/16 in |

| ELS120NC12-(X) | 100° Reduced Flush Shear | 6Al-4V Titanium | 3/8 in |

| ELS120NF6-(Y) | 100° Reduced Flush Shear | 6Al-4V Titanium | 3/16 in |

| ELS120NF8-(Y) | 100° Reduced Flush Shear | 6Al-4V Titanium | 1/4 in |

| ELS120NF10-(Y) | 100° Reduced Flush Shear | 6Al-4V Titanium | 5/16 in |

| ELS120NF12-(Y) | 100° Reduced Flush Shear | 6Al-4V Titanium | 3/8 in |

| ELS120NN6-(Y) | 100° Reduced Flush Shear | 6Al-4V Titanium | 3/16 in |

| ELS120NN8-(Y) | 100° Reduced Flush Shear | 6Al-4V Titanium | 1/4 in |

| ELS120NN10-(Y) | 100° Reduced Flush Shear | 6Al-4V Titanium | 5/16 in |

| ELS120NN12-(Y) | 100° Reduced Flush Shear | 6Al-4V Titanium | 3/8 in |

| ELS120NC6-(Y) | 100° Reduced Flush Shear | 6Al-4V Titanium | 3/16 in |

| ELS120NC8-(Y) | 100° Reduced Flush Shear | 6Al-4V Titanium | 1/4 in |

| ELS120NC10-(Y) | 100° Reduced Flush Shear | 6Al-4V Titanium | 5/16 in |

| ELS120NC12-(Y) | 100° Reduced Flush Shear | 6Al-4V Titanium | 3/8 in |

| ELS220NF5-( ) | Protruding Shear | 6Al-4V Titanium | 5/32 in |

| ELS220NF6-( ) | Protruding Shear | 6Al-4V Titanium | 3/16 in |

| ELS220NF8-( ) | Protruding Shear | 6Al-4V Titanium | 1/4 in |

| ELS220NF10-( ) | Protruding Shear | 6Al-4V Titanium | 5/16 in |

| ELS220NF12-( ) | Protruding Shear | 6Al-4V Titanium | 3/8 in |

| ELS220NN5-( ) | Protruding Shear | 6Al-4V Titanium | 5/32 in |

| ELS220NN6-( ) | Protruding Shear | 6Al-4V Titanium | 3/16 in |

| ELS220NN8-( ) | Protruding Shear | 6Al-4V Titanium | 1/4 in |

| ELS220NN10-( ) | Protruding Shear | 6Al-4V Titanium | 5/16 in |

| ELS220NN12-( ) | Protruding Shear | 6Al-4V Titanium | 3/8 in |

| ELS220NC5-( ) | Protruding Shear | 6Al-4V Titanium | 5/32 in |

| ELS220NC6-( ) | Protruding Shear | 6Al-4V Titanium | 3/16 in |

| ELS220NC8-( ) | Protruding Shear | 6Al-4V Titanium | 1/4 in |

| ELS220NC10-( ) | Protruding Shear | 6Al-4V Titanium | 5/16 in |

| ELS220NC12-( ) | Protruding Shear | 6Al-4V Titanium | 3/8 in |

| ELS220NF5-(X) | Protruding Shear | 6Al-4V Titanium | 5/32 in |

| ELS220NF6-(X) | Protruding Shear | 6Al-4V Titanium | 3/16 in |

| ELS220NF8-(X) | Protruding Shear | 6Al-4V Titanium | 1/4 in |

| ELS220NF10-(X) | Protruding Shear | 6Al-4V Titanium | 5/16 in |

| ELS220NF12-(X) | Protruding Shear | 6Al-4V Titanium | 3/8 in |

| ELS220NN5-(X) | Protruding Shear | 6Al-4V Titanium | 5/32 in |

| ELS220NN6-(X) | Protruding Shear | 6Al-4V Titanium | 3/16 in |

| ELS220NN8-(X) | Protruding Shear | 6Al-4V Titanium | 1/4 in |

| ELS220NN10-(X) | Protruding Shear | 6Al-4V Titanium | 5/16 in |

| ELS220NN12-(X) | Protruding Shear | 6Al-4V Titanium | 3/8 in |

| ELS220NC5-(X) | Protruding Shear | 6Al-4V Titanium | 5/32 in |

| ELS220NC6-(X) | Protruding Shear | 6Al-4V Titanium | 3/16 in |

| ELS220NC8-(X) | Protruding Shear | 6Al-4V Titanium | 1/4 in |

| ELS220NC10-(X) | Protruding Shear | 6Al-4V Titanium | 5/16 in |

| ELS220NC12-(X) | Protruding Shear | 6Al-4V Titanium | 3/8 in |

| ELS220NF6-(Y) | Protruding Shear | 6Al-4V Titanium | 3/16 in |

| ELS220NF8-(Y) | Protruding Shear | 6Al-4V Titanium | 1/4 in |

| ELS220NF10-(Y) | Protruding Shear | 6Al-4V Titanium | 5/16 in |

| ELS220NF12-(Y) | Protruding Shear | 6Al-4V Titanium | 3/8 in |

| ELS220NN6-(Y) | Protruding Shear | 6Al-4V Titanium | 3/16 in |

| ELS220NN8-(Y) | Protruding Shear | 6Al-4V Titanium | 1/4 in |

| ELS220NN10-(Y) | Protruding Shear | 6Al-4V Titanium | 5/16 in |

| ELS220NN12-(Y) | Protruding Shear | 6Al-4V Titanium | 3/8 in |

| ELS220NC6-(Y) | Protruding Shear | 6Al-4V Titanium | 3/16 in |

| ELS220NC8-(Y) | Protruding Shear | 6Al-4V Titanium | 1/4 in |

| ELS220NC10-(Y) | Protruding Shear | 6Al-4V Titanium | 5/16 in |

| ELS220NC12-(Y) | Protruding Shear | 6Al-4V Titanium | 3/8 in |

| ELS320NF5-( ) | 100° Flush Tension | 6Al-4V Titanium | 5/32 in |

| ELS320NF6-( ) | 100° Flush Tension | 6Al-4V Titanium | 3/16 in |

| ELS320NF8-( ) | 100° Flush Tension | 6Al-4V Titanium | 1/4 in |

| ELS320NF10-( ) | 100° Flush Tension | 6Al-4V Titanium | 5/16 in |

| ELS320NF12-( ) | 100° Flush Tension | 6Al-4V Titanium | 3/8 in |

| ELS320NN5-( ) | 100° Flush Tension | 6Al-4V Titanium | 5/32 in |

| ELS320NN6-( ) | 100° Flush Tension | 6Al-4V Titanium | 3/16 in |

| ELS320NN8-( ) | 100° Flush Tension | 6Al-4V Titanium | 1/4 in |

| ELS320NN10-( ) | 100° Flush Tension | 6Al-4V Titanium | 5/16 in |

| ELS320NN12-( ) | 100° Flush Tension | 6Al-4V Titanium | 3/8 in |

| ELS320NC5-( ) | 100° Flush Tension | 6Al-4V Titanium | 5/32 in |

| ELS320NC6-( ) | 100° Flush Tension | 6Al-4V Titanium | 3/16 in |

| ELS320NC8-( ) | 100° Flush Tension | 6Al-4V Titanium | 1/4 in |

| ELS320NC10-( ) | 100° Flush Tension | 6Al-4V Titanium | 5/16 in |

| ELS320NC12-( ) | 100° Flush Tension | 6Al-4V Titanium | 3/8 in |

| ELS320NF5-(X) | 100° Flush Tension | 6Al-4V Titanium | 5/32 in |

| ELS320NF6-(X) | 100° Flush Tension | 6Al-4V Titanium | 3/16 in |

| ELS320NF8-(X) | 100° Flush Tension | 6Al-4V Titanium | 1/4 in |

| ELS320NF10-(X) | 100° Flush Tension | 6Al-4V Titanium | 5/16 in |

| ELS320NF12-(X) | 100° Flush Tension | 6Al-4V Titanium | 3/8 in |

| ELS320NN5-(X) | 100° Flush Tension | 6Al-4V Titanium | 5/32 in |

| ELS320NN6-(X) | 100° Flush Tension | 6Al-4V Titanium | 3/16 in |

| ELS320NN8-(X) | 100° Flush Tension | 6Al-4V Titanium | 1/4 in |

| ELS320NN10-(X) | 100° Flush Tension | 6Al-4V Titanium | 5/16 in |

| ELS320NN12-(X) | 100° Flush Tension | 6Al-4V Titanium | 3/8 in |

| ELS320NC5-(X) | 100° Flush Tension | 6Al-4V Titanium | 5/32 in |

| ELS320NC6-(X) | 100° Flush Tension | 6Al-4V Titanium | 3/16 in |

| ELS320NC8-(X) | 100° Flush Tension | 6Al-4V Titanium | 1/4 in |

| ELS320NC10-(X) | 100° Flush Tension | 6Al-4V Titanium | 5/16 in |

| ELS320NC12-(X) | 100° Flush Tension | 6Al-4V Titanium | 3/8 in |

| ELS320NF6-(Y) | 100° Flush Tension | 6Al-4V Titanium | 3/16 in |

| ELS320NF8-(Y) | 100° Flush Tension | 6Al-4V Titanium | 1/4 in |

| ELS320NF10-(Y) | 100° Flush Tension | 6Al-4V Titanium | 5/16 in |

| ELS320NF12-(Y) | 100° Flush Tension | 6Al-4V Titanium | 3/8 in |

| ELS320NN6-(Y) | 100° Flush Tension | 6Al-4V Titanium | 3/16 in |

| ELS320NN8-(Y) | 100° Flush Tension | 6Al-4V Titanium | 1/4 in |

| ELS320NN10-(Y) | 100° Flush Tension | 6Al-4V Titanium | 5/16 in |

| ELS320NN12-(Y) | 100° Flush Tension | 6Al-4V Titanium | 3/8 in |

| ELS320NC6-(Y) | 100° Flush Tension | 6Al-4V Titanium | 3/16 in |

| ELS320NC8-(Y) | 100° Flush Tension | 6Al-4V Titanium | 1/4 in |

| ELS320NC10-(Y) | 100° Flush Tension | 6Al-4V Titanium | 5/16 in |

| ELS320NC12-(Y) | 100° Flush Tension | 6Al-4V Titanium | 3/8 in |

| ELS420NC5-( ) | Protruding Tension | 6Al-4V Titanium | 5/32 in |

| ELS420NC6-( ) | Protruding Tension | 6Al-4V Titanium | 3/16 in |

| ELS420NC8-( ) | Protruding Tension | 6Al-4V Titanium | 1/4 in |

| ELS420NC10-( ) | Protruding Tension | 6Al-4V Titanium | 5/16 in |

| ELS420NC12-( ) | Protruding Tension | 6Al-4V Titanium | 3/8 in |

| ELS420NN5-( ) | Protruding Tension | 6Al-4V Titanium | 5/32 in |

| ELS420NN6-( ) | Protruding Tension | 6Al-4V Titanium | 3/16 in |

| ELS420NN8-( ) | Protruding Tension | 6Al-4V Titanium | 1/4 in |

| ELS420NN10-( ) | Protruding Tension | 6Al-4V Titanium | 5/16 in |

| ELS420NN12-( ) | Protruding Tension | 6Al-4V Titanium | 3/8 in |

| ELS420NC5-(X) | Protruding Tension | 6Al-4V Titanium | 5/32 in |

| ELS420NC6-(X) | Protruding Tension | 6Al-4V Titanium | 3/16 in |

| ELS420NC8-(X) | Protruding Tension | 6Al-4V Titanium | 1/4 in |

| ELS420NC10-(X) | Protruding Tension | 6Al-4V Titanium | 5/16 in |

| ELS420NC12-(X) | Protruding Tension | 6Al-4V Titanium | 3/8 in |

| ELS420NN5-(X) | Protruding Tension | 6Al-4V Titanium | 5/32 in |

| ELS420NN6-(X) | Protruding Tension | 6Al-4V Titanium | 3/16 in |

| ELS420NN8-(X) | Protruding Tension | 6Al-4V Titanium | 1/4 in |

| ELS420NN10-(X) | Protruding Tension | 6Al-4V Titanium | 5/16 in |

| ELS420NN12-(X) | Protruding Tension | 6Al-4V Titanium | 3/8 in |

| ELS420NC6-(Y) | Protruding Tension | 6Al-4V Titanium | 3/16 in |

| ELS420NC8-(Y) | Protruding Tension | 6Al-4V Titanium | 1/4 in |

| ELS420NC10-(Y) | Protruding Tension | 6Al-4V Titanium | 5/16 in |

| ELS420NC12-(Y) | Protruding Tension | 6Al-4V Titanium | 3/8 in |

| ELS420NN6-(Y) | Protruding Tension | 6Al-4V Titanium | 3/16 in |

| ELS420NN8-(Y) | Protruding Tension | 6Al-4V Titanium | 1/4 in |

| ELS420NN10-(Y) | Protruding Tension | 6Al-4V Titanium | 5/16 in |

| ELS420NN12-(Y) | Protruding Tension | 6Al-4V Titanium | 3/8 in |

| ELS9020NF5-( ) | 130° Flush Shear | 6Al-4V Titanium | 5/32 in |

| ELS9020NF6-( ) | 130° Flush Shear | 6Al-4V Titanium | 3/16 in |

| ELS9020NF8-( ) | 130° Flush Shear | 6Al-4V Titanium | 1/4 in |

| ELS9020NF10-( ) | 130° Flush Shear | 6Al-4V Titanium | 5/16 in |

| ELS9020NF12-( ) | 130° Flush Shear | 6Al-4V Titanium | 3/8 in |

| ELS9020NN5-( ) | 130° Flush Shear | 6Al-4V Titanium | 5/32 in |

| ELS9020NN6-( ) | 130° Flush Shear | 6Al-4V Titanium | 3/16 in |

| ELS9020NN8-( ) | 130° Flush Shear | 6Al-4V Titanium | 1/4 in |

| ELS9020NN10-( ) | 130° Flush Shear | 6Al-4V Titanium | 5/16 in |

| ELS9020NN12-( ) | 130° Flush Shear | 6Al-4V Titanium | 3/8 in |

| ELS9020NC5-( ) | 130° Flush Shear | 6Al-4V Titanium | 5/32 in |

| ELS9020NC6-( ) | 130° Flush Shear | 6Al-4V Titanium | 3/16 in |

| ELS9020NC8-( ) | 130° Flush Shear | 6Al-4V Titanium | 1/4 in |

| ELS9020NC10-( ) | 130° Flush Shear | 6Al-4V Titanium | 5/16 in |

| ELS9020NC12-( ) | 130° Flush Shear | 6Al-4V Titanium | 3/8 in |

| ELS9020NF5-(X) | 130° Flush Shear | 6Al-4V Titanium | 5/32 in |

| ELS9020NF6-(X) | 130° Flush Shear | 6Al-4V Titanium | 3/16 in |

| ELS9020NF8-(X) | 130° Flush Shear | 6Al-4V Titanium | 1/4 in |

| ELS9020NF10-(X) | 130° Flush Shear | 6Al-4V Titanium | 5/16 in |

| ELS9020NF12-(X) | 130° Flush Shear | 6Al-4V Titanium | 3/8 in |

| ELS9020NN5-(X) | 130° Flush Shear | 6Al-4V Titanium | 5/32 in |

| ELS9020NN6-(X) | 130° Flush Shear | 6Al-4V Titanium | 3/16 in |

| ELS9020NN8-(X) | 130° Flush Shear | 6Al-4V Titanium | 1/4 in |

| ELS9020NN10-(X) | 130° Flush Shear | 6Al-4V Titanium | 5/16 in |

| ELS9020NN12-(X) | 130° Flush Shear | 6Al-4V Titanium | 3/8 in |

| ELS9020NC5-(X) | 130° Flush Shear | 6Al-4V Titanium | 5/32 in |

| ELS9020NC6-(X) | 130° Flush Shear | 6Al-4V Titanium | 3/16 in |

| ELS9020NC8-(X) | 130° Flush Shear | 6Al-4V Titanium | 1/4 in |

| ELS9020NC10-(X) | 130° Flush Shear | 6Al-4V Titanium | 5/16 in |

| ELS9020NC12-(X) | 130° Flush Shear | 6Al-4V Titanium | 3/8 in |

| ELS9020NF6-(Y) | 130° Flush Shear | 6Al-4V Titanium | 3/16 in |

| ELS9020NF8-(Y) | 130° Flush Shear | 6Al-4V Titanium | 1/4 in |

| ELS9020NF10-(Y) | 130° Flush Shear | 6Al-4V Titanium | 5/16 in |

| ELS9020NF12-(Y) | 130° Flush Shear | 6Al-4V Titanium | 3/8 in |

| ELS9020NN6-(Y) | 130° Flush Shear | 6Al-4V Titanium | 3/16 in |

| ELS9020NN8-(Y) | 130° Flush Shear | 6Al-4V Titanium | 1/4 in |

| ELS9020NN10-(Y) | 130° Flush Shear | 6Al-4V Titanium | 5/16 in |

| ELS9020NN12-(Y) | 130° Flush Shear | 6Al-4V Titanium | 3/8 in |

| ELS9020NC6-(Y) | 130° Flush Shear | 6Al-4V Titanium | 3/16 in |

| ELS9020NC8-(Y) | 130° Flush Shear | 6Al-4V Titanium | 1/4 in |

| ELS9020NC10-(Y) | 130° Flush Shear | 6Al-4V Titanium | 5/16 in |

| ELS9020NC12-(Y) | 130° Flush Shear | 6Al-4V Titanium | 3/8 in |

| ELS120JC5-( ) | 100° Reduced Flush Shear | 6Al-4V Titanium | 5/32 in |

| ELS120JC6-( ) | 100° Reduced Flush Shear | 6Al-4V Titanium | 3/16 in |

| ELS120JC8-( ) | 100° Reduced Flush Shear | 6Al-4V Titanium | 1/4 in |

| ELS120JC10-( ) | 100° Reduced Flush Shear | 6Al-4V Titanium | 5/16 in |

| ELS120JC12-( ) | 100° Reduced Flush Shear | 6Al-4V Titanium | 3/8 in |

| ELS120JC5-(X) | 100° Reduced Flush Shear | 6Al-4V Titanium | 5/32 in |

| ELS120JC6-(X) | 100° Reduced Flush Shear | 6Al-4V Titanium | 3/16 in |

| ELS120JC8-(X) | 100° Reduced Flush Shear | 6Al-4V Titanium | 1/4 in |

| ELS120JC10-(X) | 100° Reduced Flush Shear | 6Al-4V Titanium | 5/16 in |

| ELS120JC12-(X) | 100° Reduced Flush Shear | 6Al-4V Titanium | 3/8 in |

| ELS120JC6-(Y) | 100° Reduced Flush Shear | 6Al-4V Titanium | 3/16 in |

| ELS120JC8-(Y) | 100° Reduced Flush Shear | 6Al-4V Titanium | 1/4 in |

| ELS120JC10-(Y) | 100° Reduced Flush Shear | 6Al-4V Titanium | 5/16 in |

| ELS120JC12-(Y) | 100° Reduced Flush Shear | 6Al-4V Titanium | 3/8 in |

| ELS220JC5-( ) | Protruding Shear | 6Al-4V Titanium | 5/32 in |

| ELS220JC6-( ) | Protruding Shear | 6Al-4V Titanium | 3/16 in |

| ELS220JC8-( ) | Protruding Shear | 6Al-4V Titanium | 1/4 in |

| ELS220JC10-( ) | Protruding Shear | 6Al-4V Titanium | 5/16 in |

| ELS220JC12-( ) | Protruding Shear | 6Al-4V Titanium | 3/8 in |

| ELS220JC5-(X) | Protruding Shear | 6Al-4V Titanium | 5/32 in |

| ELS220JC6-(X) | Protruding Shear | 6Al-4V Titanium | 3/16 in |

| ELS220JC8-(X) | Protruding Shear | 6Al-4V Titanium | 1/4 in |

| ELS220JC10-(X) | Protruding Shear | 6Al-4V Titanium | 5/16 in |

| ELS220JC12-(X) | Protruding Shear | 6Al-4V Titanium | 3/8 in |

| ELS220JC6-(Y) | Protruding Shear | 6Al-4V Titanium | 3/16 in |

| ELS220JC8-(Y) | Protruding Shear | 6Al-4V Titanium | 1/4 in |

| ELS220JC10-(Y) | Protruding Shear | 6Al-4V Titanium | 5/16 in |

| ELS220JC12-(Y) | Protruding Shear | 6Al-4V Titanium | 3/8 in |

| ELS320JC5-( ) | 100° Flush Tension | 6Al-4V Titanium | 5/32 in |

| ELS320JC6-( ) | 100° Flush Tension | 6Al-4V Titanium | 3/16 in |

| ELS320JC8-( ) | 100° Flush Tension | 6Al-4V Titanium | 1/4 in |

| ELS320JC10-( ) | 100° Flush Tension | 6Al-4V Titanium | 5/16 in |

| ELS320JC12-( ) | 100° Flush Tension | 6Al-4V Titanium | 3/8 in |

| ELS320JC5-(X) | 100° Flush Tension | 6Al-4V Titanium | 5/32 in |

| ELS320JC6-(X) | 100° Flush Tension | 6Al-4V Titanium | 3/16 in |

| ELS320JC8-(X) | 100° Flush Tension | 6Al-4V Titanium | 1/4 in |

| ELS320JC10-(X) | 100° Flush Tension | 6Al-4V Titanium | 5/16 in |

| ELS320JC12-(X) | 100° Flush Tension | 6Al-4V Titanium | 3/8 in |

| ELS320JC6-(Y) | 100° Flush Tension | 6Al-4V Titanium | 3/16 in |

| ELS320JC8-(Y) | 100° Flush Tension | 6Al-4V Titanium | 1/4 in |

| ELS320JC10-(Y) | 100° Flush Tension | 6Al-4V Titanium | 5/16 in |

| ELS320JC12-(Y) | 100° Flush Tension | 6Al-4V Titanium | 3/8 in |

| ELS420JC5-( ) | Protruding Tension | 6Al-4V Titanium | 5/32 in |

| ELS420JC6-( ) | Protruding Tension | 6Al-4V Titanium | 3/16 in |

| ELS420JC8-( ) | Protruding Tension | 6Al-4V Titanium | 1/4 in |

| ELS420JC10-( ) | Protruding Tension | 6Al-4V Titanium | 5/16 in |

| ELS420JC12-( ) | Protruding Tension | 6Al-4V Titanium | 3/8 in |

| ELS420JC5-(X) | Protruding Tension | 6Al-4V Titanium | 5/32 in |

| ELS420JC6-(X) | Protruding Tension | 6Al-4V Titanium | 3/16 in |

| ELS420JC8-(X) | Protruding Tension | 6Al-4V Titanium | 1/4 in |

| ELS420JC10-(X) | Protruding Tension | 6Al-4V Titanium | 5/16 in |

| ELS420JC12-(X) | Protruding Tension | 6Al-4V Titanium | 3/8 in |

| ELS420JC6-(Y) | Protruding Tension | 6Al-4V Titanium | 3/16 in |

| ELS420JC8-(Y) | Protruding Tension | 6Al-4V Titanium | 1/4 in |

| ELS420JC10-(Y) | Protruding Tension | 6Al-4V Titanium | 5/16 in |

| ELS420JC12-(Y) | Protruding Tension | 6Al-4V Titanium | 3/8 in |

| ELS9020JC5-( ) | 130° Flush Shear | 6Al-4V Titanium | 5/32 in |

| ELS9020JC6-( ) | 130° Flush Shear | 6Al-4V Titanium | 3/16 in |

| ELS9020JC8-( ) | 130° Flush Shear | 6Al-4V Titanium | 1/4 in |

| ELS9020JC10-( ) | 130° Flush Shear | 6Al-4V Titanium | 5/16 in |

| ELS9020JC12-( ) | 130° Flush Shear | 6Al-4V Titanium | 3/8 in |

| ELS9020JC5-(X) | 130° Flush Shear | 6Al-4V Titanium | 5/32 in |

| ELS9020JC6-(X) | 130° Flush Shear | 6Al-4V Titanium | 3/16 in |

| ELS9020JC8-(X) | 130° Flush Shear | 6Al-4V Titanium | 1/4 in |

| ELS9020JC10-(X) | 130° Flush Shear | 6Al-4V Titanium | 5/16 in |

| ELS9020JC12-(X) | 130° Flush Shear | 6Al-4V Titanium | 3/8 in |

| ELS9020JC6-(Y) | 130° Flush Shear | 6Al-4V Titanium | 3/16 in |

| ELS9020JC8-(Y) | 130° Flush Shear | 6Al-4V Titanium | 1/4 in |

| ELS9020JC10-(Y) | 130° Flush Shear | 6Al-4V Titanium | 5/16 in |

| ELS9020JC12-(Y) | 130° Flush Shear | 6Al-4V Titanium | 3/8 in |

Eddie-Bolt® is registered trademarks of Howmet Aerospace Inc. and/or it’s subsidiaries. Perfect Point EDM, Corp. has no affiliation with Howmet Aerospace Inc. and/or it’s subsidiaries.