E-DRILL VACUUM

LOCATOR TOOLING

Vacuum Locator Tools

Click each item to expand

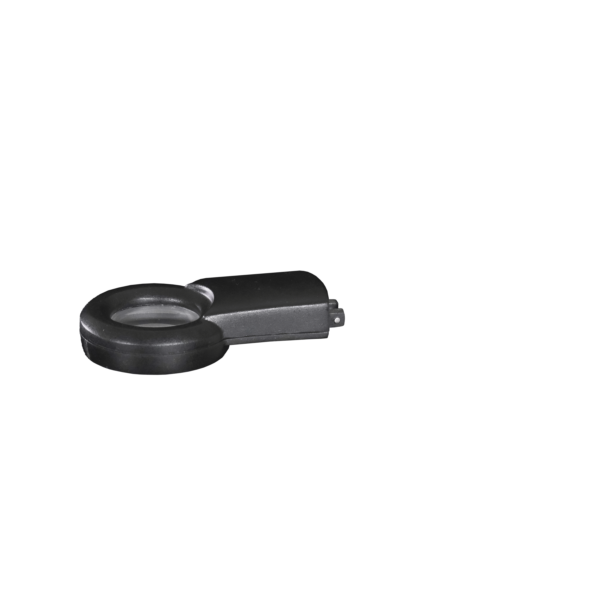

Magnifying Bombsight

Improved precision and clarity when locating

Because we can mechanically lock over a protruding head fastener, there is no need for vacuum tooling like with flush-installed fasteners. E-Drill is simply placed in the locator during the cut to hold it centered and avoid damage. One hand holds the BHL steady over the fastener with light force (just enough to seal the O-ring), while the other hand is used to hold and operate the E-Drill hand tool.

Aperture Rings

Rings sized for each fastener head

The outside diameter and sealing surface of BHL assemblies is optimized to fit between fastener heads spaced per industry standard (typically greater than 4 to1, spacing to diameter), while maximizing the footprint to enhance perpendicularity. Detailed instructions for use will follow in Section 6.

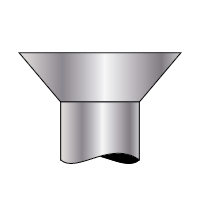

Vaccum Locator

Locks E-Drill in place when cutting

The metal inserts are removable, and each is intended to be pre-bored to suit a specific fastener head diameter. The inserts may be supplied pre-bored to a specific size upon request, or the customer may purchase piloted blanks either individually or pre-assembled, which they can bore themselves per their requirements. Hexagonal inserts are also available for specific hex-head blind fasteners, and removal of seized nuts and bolts.

CLICK TO EXPAND

Aperture Locator

Mechanical Locator