Aircraft Skin Repairs

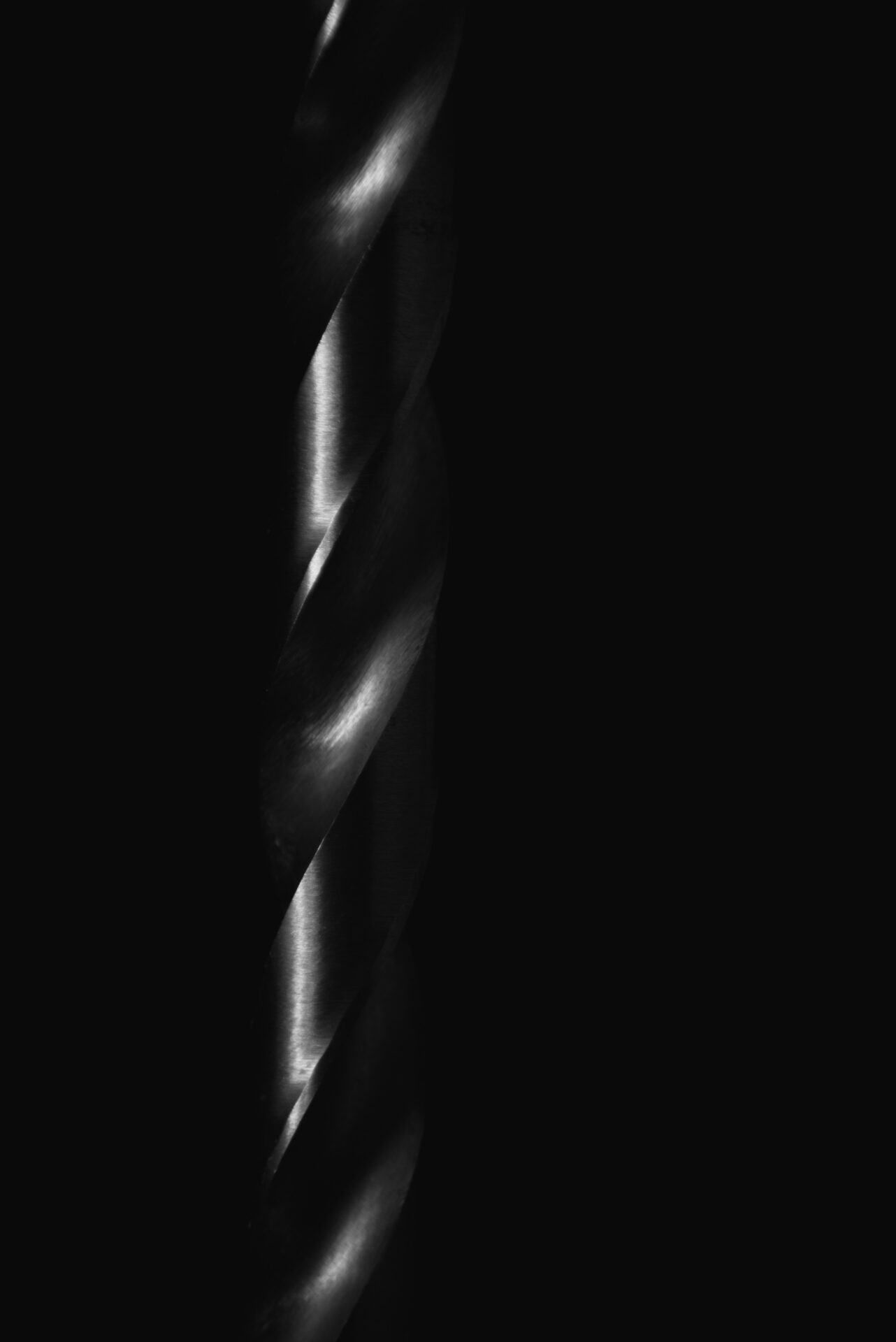

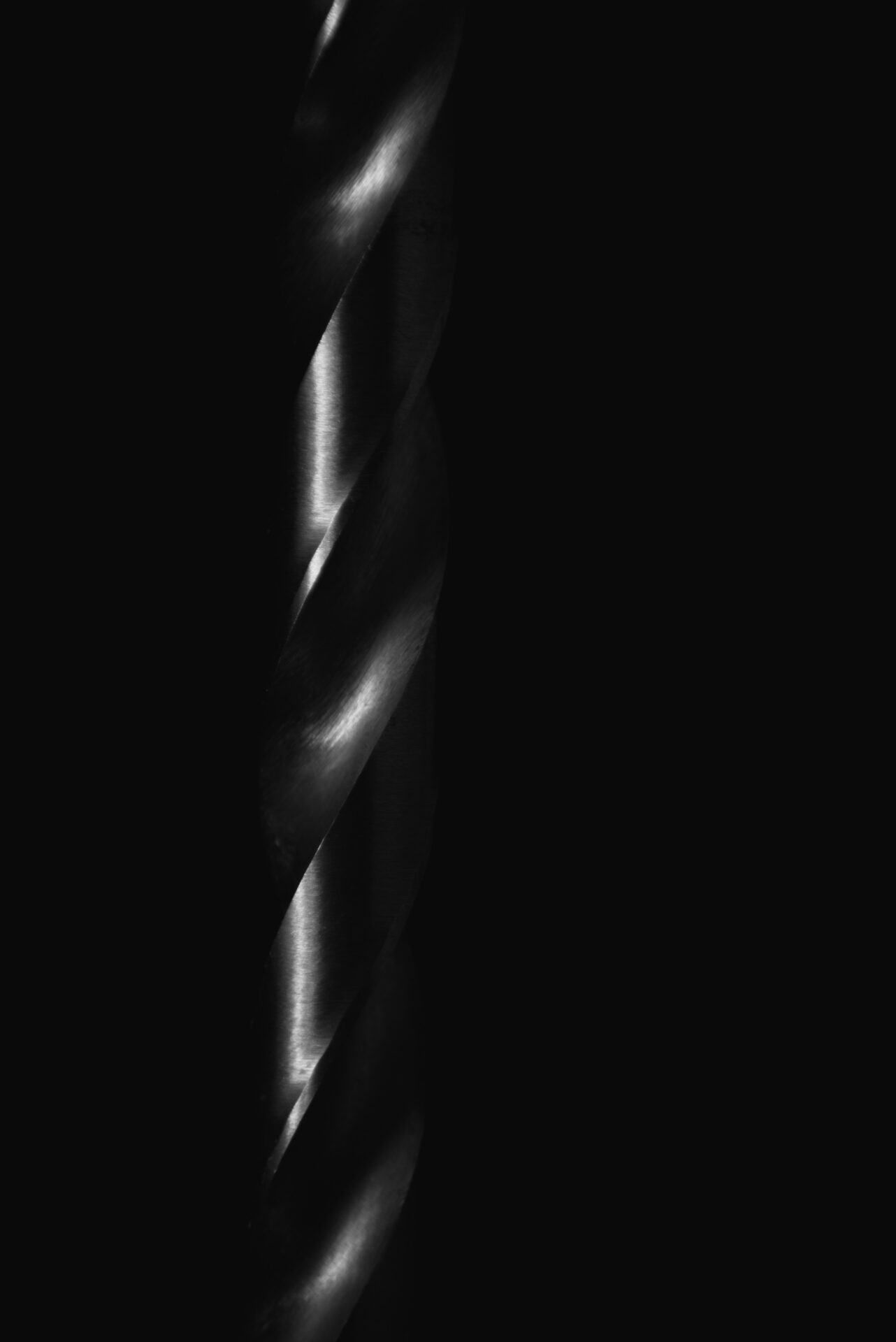

Keeping holes aligned on thin, curved skins is notoriously difficult. Vac-Exact locks to the fuselage surface and holds the drill perpendicular, preventing bit walk and reducing costly rework.

Portable, modular, precision drill fixture

Universal compatibility

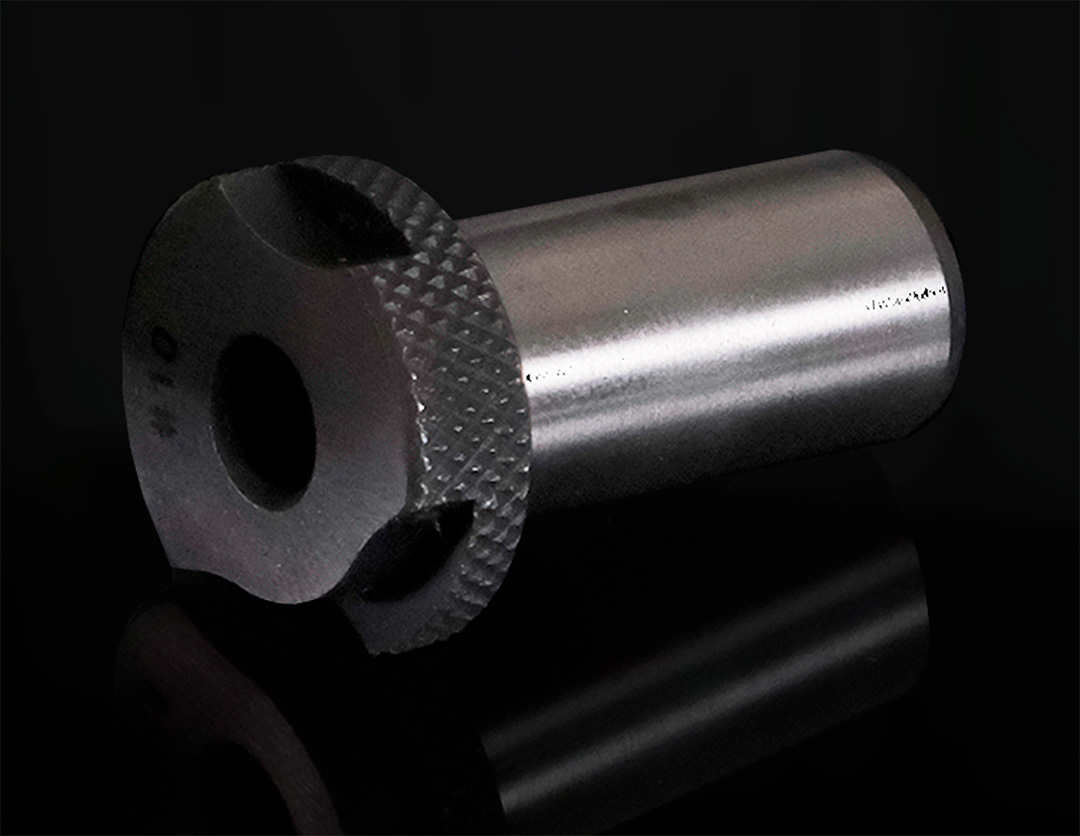

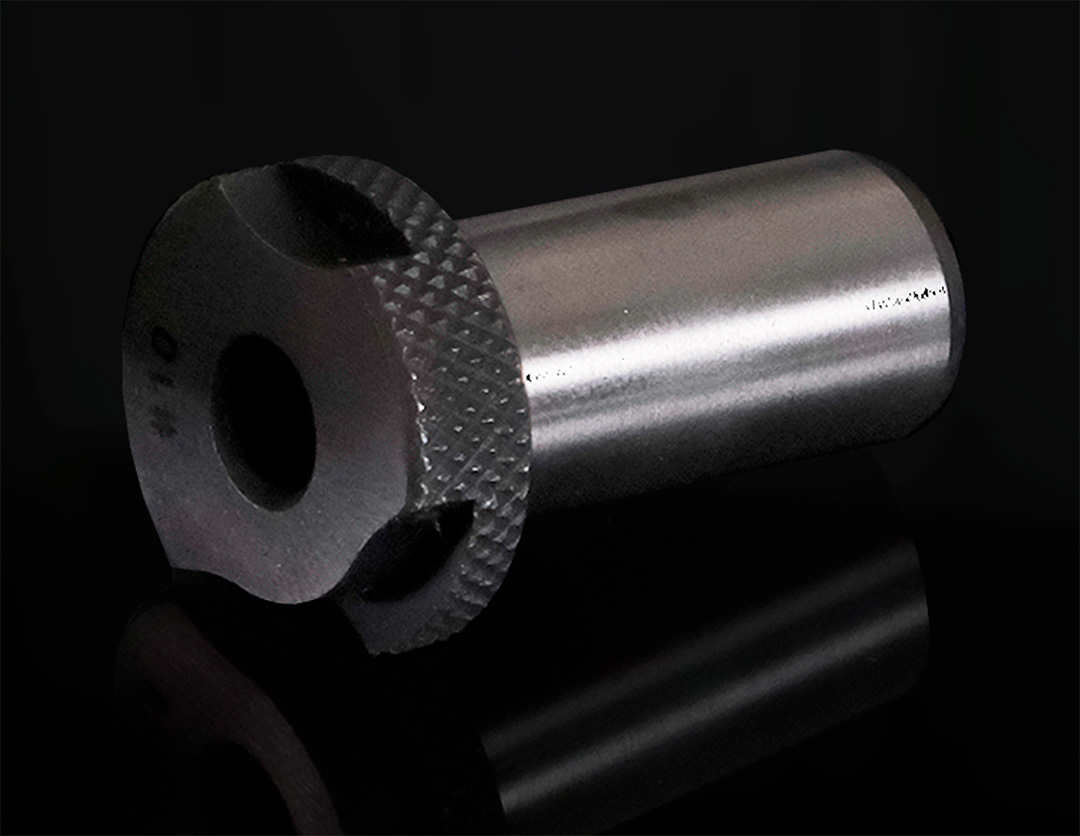

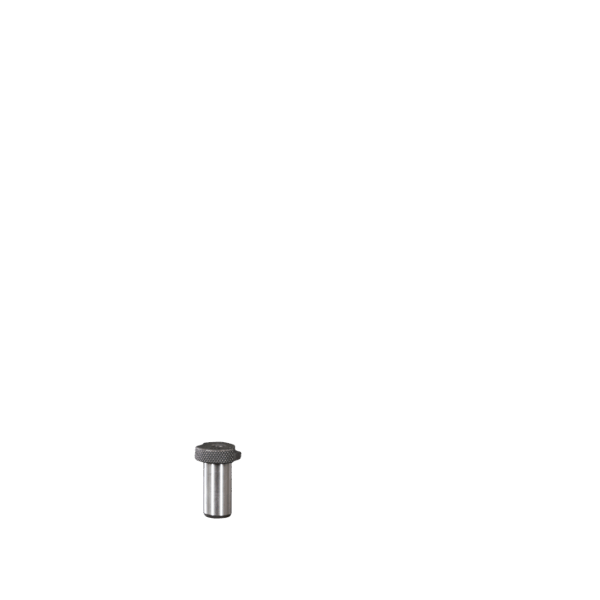

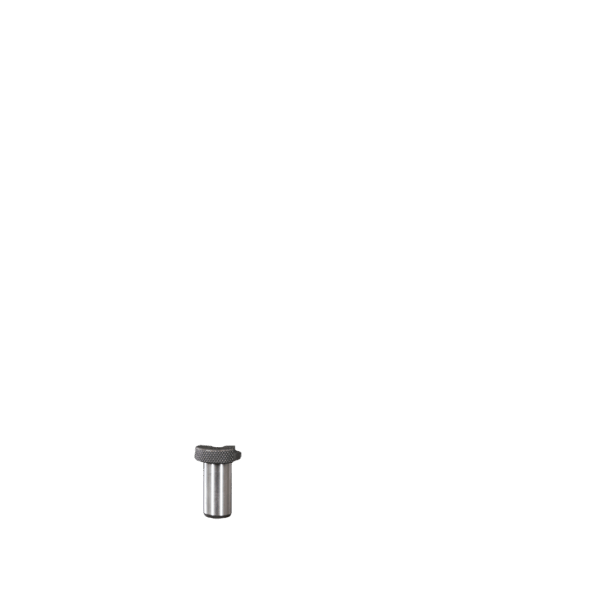

Accepts industry-standard slip-fixed renewable bushings, making Vac-Exact compatible with nearly any drill bit size. Use what you already have in the shop, or order custom sizes for specialized applications.

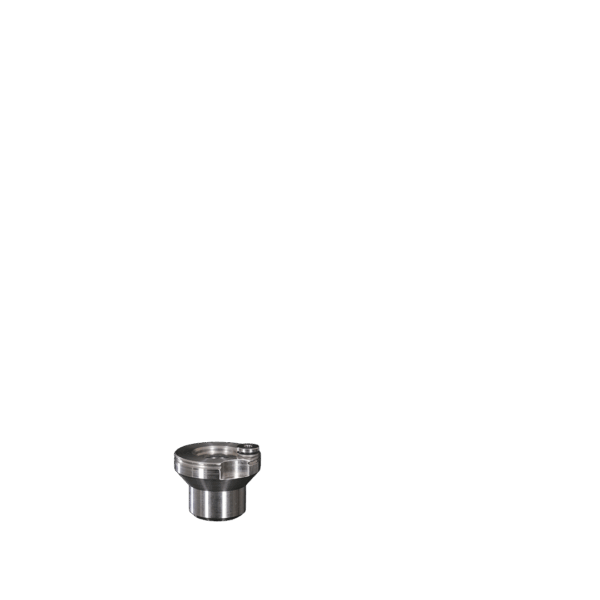

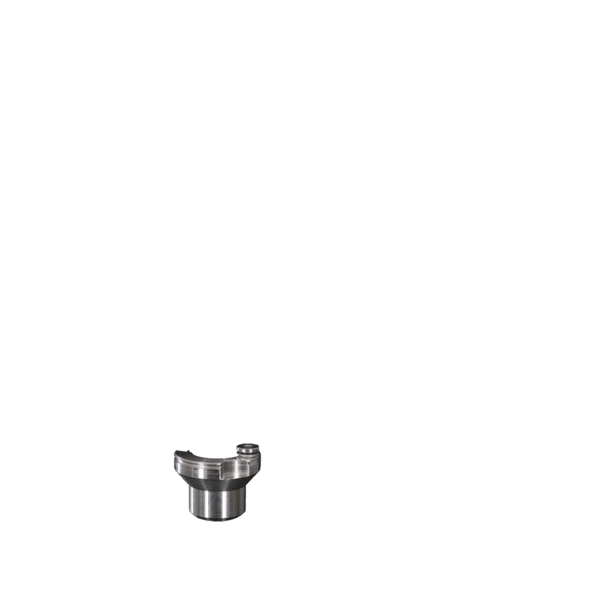

Locks bushing to the locator

Secures the drill bushing to the locator, ensuring perfect alignment and stability. This adapter bridges common bushings with Perfect Point’s proprietary fixturing for consistent, repeatable accuracy.

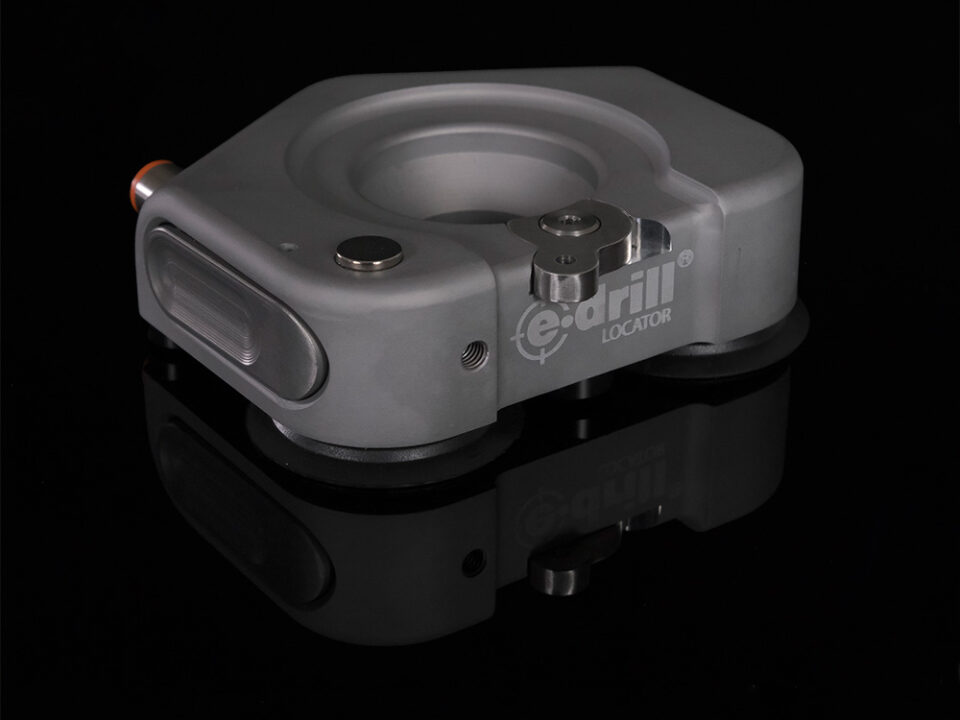

Stable positioning, simple control

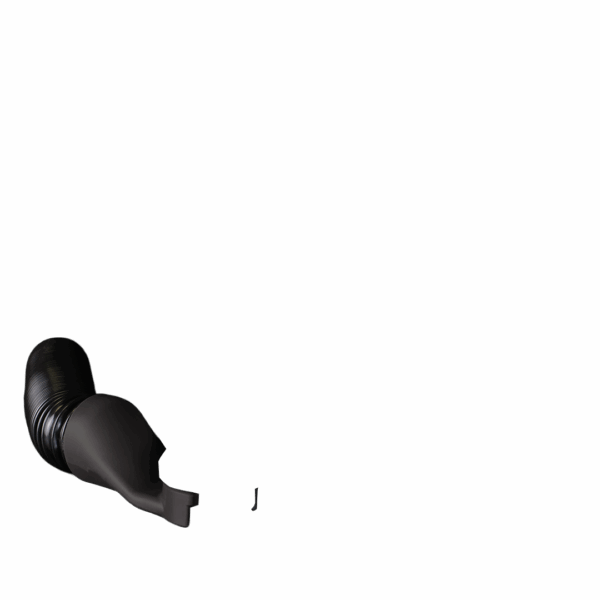

Powered by an external venturi vacuum module connected to shop air, the locator clamps firmly to flat or curved surfaces. A manual lever/button vents suction for repositioning, then re-engages to lock in place—no motors or electronics required.

Cleaner holes, reduced FOD

An optional shop-vac connection clips onto the locator body, helping remove chips and dust as you drill. It reduces cleanup effort and lowers FOD risk, while keeping the system lightweight and portable.

The right setup for every job

Precision where it matters most

From aircraft skin repairs to industrial maintenance, Vac-Exact locks in place and guides every drill for centered, perpendicular holes with less rework and cleaner results.

Keeping holes aligned on thin, curved skins is notoriously difficult. Vac-Exact locks to the fuselage surface and holds the drill perpendicular, preventing bit walk and reducing costly rework.

When a hole is off-center or oversized, re-drilling can cause the bit to wander. Vac-Exact keeps the drill steady on the new centerline, making pulling holes straightforward and precise.

Large parts that don’t fit in a drill press often require complex, expensive fixturing. Vac-Exact replaces this setup with a lightweight, portable solution, bringing perpendicular accuracy directly to the workpiece and saving time on every job.

Drilling or reaming holes in nacelle casings demands accuracy and cleanliness. Vac-Exact ensures concentric alignment while the optional debris attachment helps reduce chips around sensitive components.

Vac-Exact’s benefits extend well outside aircraft maintenance. From automotive repair and restoration to industrial fabrication, energy, and maritime applications, it provides portable precision wherever traditional fixturing isn’t practical.

View more

The Vac-Exact Drill/Ream Kit is engineered for precision and portability across diverse applications:

Precision: Vacuum alignment + guided bushings = no walking, no wobbling.

Clean: Optional extraction adapter reduces FOD and cleanup time.

Versatile: Works on curves, accepts standard tools—complements E-Drill for full workflows.

Easy: Quick vacuum setup, no complex fixturing or training required.

Want perfectly centered, perpendicular holes on the go?