E-Drill Academy

Access step-by-step training and troubleshooting guides to help your team get the most out of E-Drill anytime, anywhere.

Visit E-Drill Academy

Welcome to our FAQ hub—your one-stop resource for answers to the most common questions about E-Drill, S-Blaster, and Perfect Point EDM. Use the search, filter, or sorting tools below to quickly find the information you need.

If you don’t see your answer here, visit our E-Drill Academy for in-depth training videos or explore our Documentation Library for detailed manuals, guides, and technical resources. Or as always, Contact Us, to speak with a Perfect Point Rep.

Have questions or need immediate support? Reach our team directly for sales inquiries, technical assistance, or live agent help.

Access step-by-step training and troubleshooting guides to help your team get the most out of E-Drill anytime, anywhere.

Visit E-Drill AcademyFind the latest user guides, manuals, and legacy documentation for E-Drill and S-Blaster systems, all in one place.

View Documentation

No special utilities are required—E-Drill is designed to run on standard shop infrastructure. It uses regular tap water, standard power, and shop air, making setup simple in most aerospace maintenance environments.

No. E-Drill requires a clean, conductive surface to start the EDM process and cannot cut through paint or coatings. Our S-Blaster tool is specifically designed to remove paint and coatings from fastener heads quickly and safely before using E-Drill.

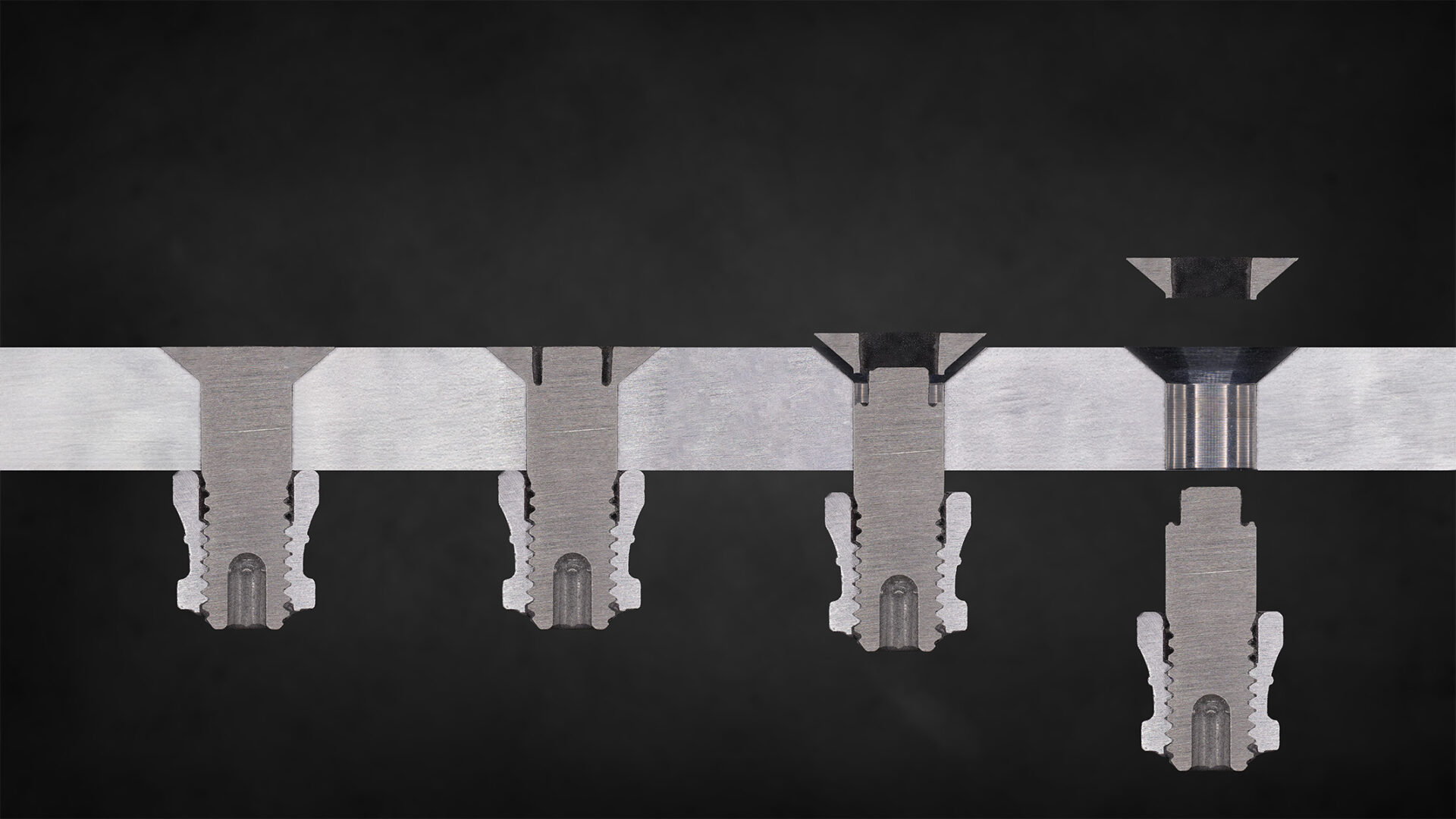

E-Drill’s main consumables are electrodes and filters. Each electrode typically lasts for 50–80 fastener removals, while the deionizing and sediment filters are replaced about every 5,500 cuts to maintain peak cutting performance.

E-Drill is specifically engineered to avoid contact with the parent material. Its EDM process is guided, undersized relative to the fastener, and stops at a controlled depth to prevent hole damage. In the rare case of setup error, standard aerospace oversizing repairs fully restore structural integrity.

Yes. E-Drill can be used on curved, vertical, or even inverted surfaces. With vacuum locator tooling or button-head bushings, the system maintains alignment and stability in any orientation, ensuring precise fastener removal without added fixturing.

E-Drill comes with 10’ or 30’ hoses. The lighter weight of E-Drill 2.0 also makes it easier to mount on lifts for hard-to-reach locations, such as the top of a vertical stabilizer on a large aircraft.

Are fasteners pre-programmed into the machine?

No, E-Drill systems do not come with pre-loaded fastener profiles — and that’s by design. Every maintenance operation is different, and our goal is to tailor the system to your specific use cases. That’s why every E-Drill purchase includes two full days of on-site training and setup. During this time, a technician from our team will help you build and program the fastener types you encounter most often using the built-in Build Fastener tool.

In addition to hands-on training, we teach your team how to easily add and edit fastener profiles as your needs evolve. Whether you’re working with Hi-Loks, Jo-Bolts, or unique custom hardware, your E-Drill system can be configured accordingly. For step-by-step instructions, visit our E-Drill Academy or download the user guide from our Documentation page.

E-Drill removes only the fastener material itself, not the structure around it. The system uses a precisely programmed EDM process that cuts to a set depth and uses electrodes sized smaller than the fastener shank. Whether the fastener is in metal, composite, or another material, E-Drill avoids contacting or damaging the parent material.

E-Drill is designed with operator safety in mind. The EDM process is not harmful to human contact, as the body isn’t conductive enough for the discharge to occur. Unlike traditional drills, E-Drill requires minimal force, produces less debris, and reduces risks of repetitive strain injuries, broken drill bits, or flying fragments during fastener removal.

E-Drill replaces traditional drilling with a precision Electro-Discharge Machining (EDM) process that removes only the fastener, not the surrounding structure. Unlike twist drills that can slip, cause hole damage, and require frequent bit changes, E-Drill removes fasteners faster, safer, and more consistently—with lower rework and consumable costs.

The standard S-Blaster hose is approximately 6 feet long, providing ample reach for most aerospace maintenance tasks. Unlike traditional blast systems that require stationary booths or fixed connections, S-Blaster’s hose connects to a lightweight, backpack-mountable unit—giving technicians full freedom of movement.

Perfect Point EDM products are proudly designed, manufactured, and assembled in the USA, with final assembly and testing completed at our Huntington Beach, California headquarters. Every tool meets aerospace-grade standards for precision and reliability.

S-Blaster uses reusable plastic blast media, along with locator cups, seals, and air/HEPA filters that are replaced periodically based on usage and coating type. Detailed specifications and recommended replacement intervals are provided in the S-Blaster user guide.

Yes. S-Blaster is designed for use on delicate surfaces, using MIL-SPEC plastic media, controlled pressure, and a tightly focused blast zone to safely remove coatings without damaging composite or carbon fiber structures.

S-Blaster is engineered to use fine, aviation-grade plastic blast media that complies with MIL-SPEC standards, ensuring safe and effective surface preparation on aircraft structures. Two main types of media are available depending on the material you’re working with:

• Type II: Designed for use on metal skins and surfaces, ideal for cleaning fastener heads and coatings without scarring the metal.

• Type V: Engineered for composite materials, including carbon fiber structures. This media type ensures coating removal without compromising structural integrity.

Both media types are compatible with S-Blaster’s controlled pressure and sealed recovery system, ensuring minimal waste and maximum safety.

Yes. While S-Blaster is commonly paired with E-Drill to prepare coated fasteners for EDM removal, it’s also widely used as a standalone tool for cleaning paint and coatings off screws and fasteners where drilling isn’t required. You can purchase S-Blaster separately or as part of an E-Drill system bundle.

Typically, the blast diameter ranges from 0.250″ to 0.600″, based on locator size and settings. This ensures clean coating removal without affecting the surrounding area.

Learn more in our technical specs

S-Blaster was designed with technician mobility in mind. Unlike large blasting cabinets or bulky surface prep systems, S-Blaster is a lightweight unit that can be worn as a backpack. This backpack-mounted configuration gives users complete freedom to move around the aircraft or worksite without the need for carts, extension arms, or external blasting chambers.

Its compact form factor and ergonomic layout make it ideal for working in confined areas, on overhead surfaces, or across large aircraft sections without repositioning heavy equipment. Whether you’re depainting fasteners on a vertical stabilizer, prepping panel screws on the flight line, or touching up a composite surface in a tight crawlspace, S-Blaster goes wherever you do—no rigging or relocation required.

The system uses a finely controlled stream of plastic blast media through a masking locator cup to expose the fastener head. Blast zone is contained, media is vacuumed back, and debris is separated—clean air is expelled through a HEPA cartridge.

See the detailed operation in our S Blaster User Guide

Use the E Drill’s built in “Build Fastener” tool to generate initial electrode size and cut depth based on engineering drawing dimensions. For precision-tuned settings tailored to your operations, email info@ppedm.com with your fastener details and we’ll assist you further.

Absolutely! We encourage sending samples. We have a full testing and microscopy lab to fine‑tune performance and validate results.

Yes, we serve customers worldwide directly or via regional distributors.

For both domestic and international orders, please contact sales@ppedm.com to connect with the best local rep or partner.

Absolutely. We feature numerous customer wins and success stories in our Newsroom – Customer Wins section. Plus, additional case studies are shared privately with potential customers. Contact us if you’d like access to those details.

E-Drill is designed as a low-maintenance tool that self-calibrates with every cut. No manual calibration is required, and only minimal routine care is needed to keep the system performing at its best.

After the head is separated, the remaining stem stays in the underlying structure until you remove the panel, skin, or assembly that the fastener was securing, or remove it from an access hole or panel. This is the same process you’d encounter when using a twist drill—the stem is pushed through but does not fall free until the structure is separated.

Yes. E-Drill can remove broken bolts, screws, taps, and threaded inserts in addition to standard aerospace fasteners. Specialized tooling makes it possible to extract damaged hardware without harming the parent material.

Standard configuration covers fasteners from 3/32” to 3/8”, with other options available for larger fasteners. For larger or non-standard fastener sizes, please contact us for more information.

No—we don’t sell fasteners. However, our fastener database provides many part numbers and examples of fasteners that the E-Drill can remove.

S-Blaster is a handheld precision spot blasting tool for removing paint, sealants, fillers, corrosion, and coatings from fastener heads—without damaging nearby surfaces. It recycles media in a closed-loop system with HEPA filtration, minimizing mess and environmental impact.

E-Drill uses Electro-Discharge Machining (EDM) to remove aerospace fasteners without damaging the surrounding structure. Instead of cutting with a traditional drill bit, it uses controlled electrical energy and a circular electrode to erode the fastener head precisely, allowing it to be safely punched out.

Perfect Point EDM developed the E-Drill System to meet the aerospace industry’s growing need for innovation in fastener removal. Powered by advanced Electro-Discharge Machining (EDM) technology, E-Drill offers a precise, non-damaging solution to remove even the toughest fasteners. The system dramatically reduces removal times, minimizes risk of airframe damage, improves efficiency, and enhances technician safety.

We don’t offer fastener removal as a standalone service, but we do provide several options to help you address challenging fasteners. During live demos, we often remove fasteners directly on your coupons or articles so you can see E‑Drill in action. We also offer engineering support services, including lab-based sample testing and process validation, to help you develop effective fastener removal solutions. If you’re facing stubborn fasteners in critical structures, reach out to info@ppedm.com or visit our Services page to explore how we can assist.

Yes! Our team regularly travels to aerospace and defense sites to showcase E Drill in action.

If you’d like to see it on your fasteners or structure, let us know and we’ll schedule a demo visit to your facility.

Pricing depends on your specific configuration, since each system is customized to your needs.

For a quote or more information, contact us via our contact form or email info@ppedm.com.

E-Drill uses Electro-Discharge Machining (EDM) to remove aerospace fasteners without damaging the surrounding structure. Instead of cutting with a traditional drill bit, it uses controlled electrical energy and a circular electrode to erode the fastener head precisely, allowing it to be safely punched out.

The cost of an E-Drill system varies based on your unique operational needs. Because every aerospace maintenance environment is different, we work closely with each customer to configure a system that matches their fastener types, usage volume, and application requirements.

Absolutely. We feature numerous customer wins and success stories in our Newsroom – Customer Wins section. Plus, additional case studies are shared privately with potential customers. Contact us if you’d like access to those details.

E-Drill replaces traditional drilling with a precision Electro-Discharge Machining (EDM) process that removes only the fastener, not the surrounding structure. Unlike twist drills that can slip, cause hole damage, and require frequent bit changes, E-Drill removes fasteners faster, safer, and more consistently—with lower rework and consumable costs.