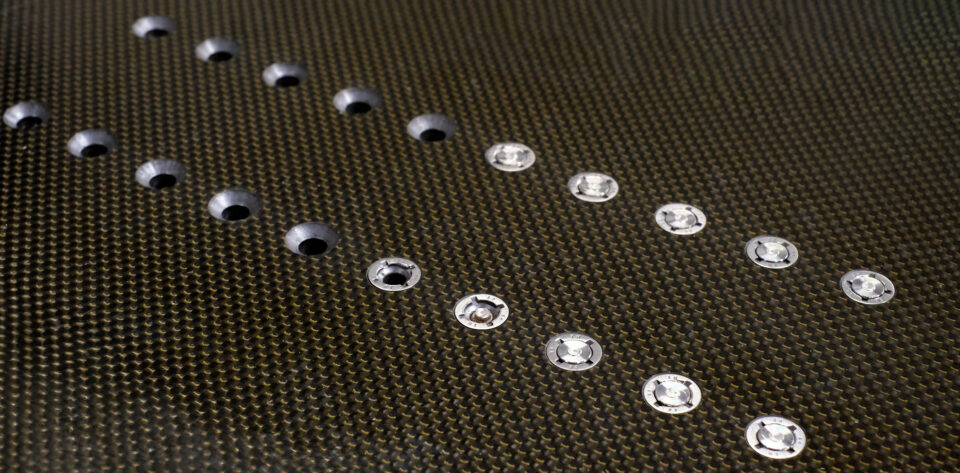

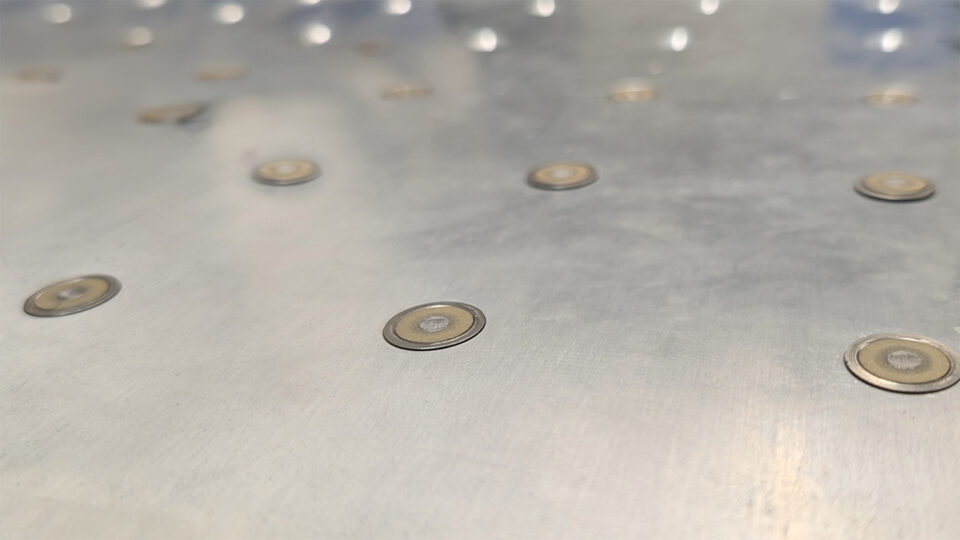

Radial-Lok® stand as a revolutionary solution in blind fastening technology, offering unparalleled hole-filling capabilities and high strength. Designed to expand uniformly throughout the entire grip length, Radial-Loks® provide enhanced fatigue strength and protection against lightning strike damage. They are widely recognized for their versatility and reliability across various aerospace applications.

Crafted from premium materials, Radial-Loks® ensure durability and performance in both aluminum and composite structures. Their uniform radial expansion, ranging from 0.002″ to 0.006″, significantly enhances the fatigue life of the fastener. Radial-Loks® are compatible with graphite and are resistant to galvanic corrosion, making them ideal for demanding aerospace environments.

Standard Removal Methods:

Traditionally, Radial-Loks® are removed using standard methods such as drilling or grinding. However, these methods can be time-consuming and labor-intensive, with the potential risk of damaging surrounding structures. Moreover, they may generate debris or foreign object debris (FOD), compromising safety and reliability.

Why E-Drill Is Better:

Utilizing E-Drill for removing Radial-Loks® offers several advantages over traditional methods. E-Drill’s precision and efficiency minimize the risk of damage to surrounding structures and reduce the likelihood of generating debris. With its non-contact technology, E-Drill provides a safer and more reliable solution for fastener removal in aerospace applications, ensuring minimal disruption

Radial-Lok Part Numbers:

| Part Number | Material | Head Style |

| MRL3210 | Titanium | Protruding, Low Profile |

| MRL3212 | Titanium | 100 Degree Tension |

Visu-Lok®, Composi-Lok®, Radial-Lok®, OSI-Bolt®, Wedgelock® are Registered Trademarks of Monogram Aerospace Fasteners, Inc. Monogram Aerospace Fasteners is a TriMas Company. Perfect Point EDM, Corp. has no affiliation with Monogram Aerospace Fasteners, Inc. or Tri-Mas.