Designed for composite laminates and adaptable to metal structures, these fasteners provide exceptional performance and reliability across a range of applications. Composi-Loks® are widely approved across various composite airframe programs globally, emphasizing their industry-standard status. Crafted from high-quality materials such as titanium or CRES (Corrosion-Resistant Steel), Composi-Loks® ensure durability and compatibility with composite and graphite structures. Their construction materials are carefully chosen to resist galvanic corrosion and provide fuel-tight sealing capabilities, meeting the stringent requirements of aerospace engineering.

Composi-Loks® boast several key features contributing to their exceptional performance. These include a large blind upset design that eliminates composite damage, easy one-sided installation facilitated by a drive nut concept, controlled clamp-up for tighter assemblies, and a patented locking feature for superior vibration resistance. Available in various shear strength versions and diameters, Composi-Loks® offer flexibility and reliability in aerospace applications.

Standard Removal Methods:

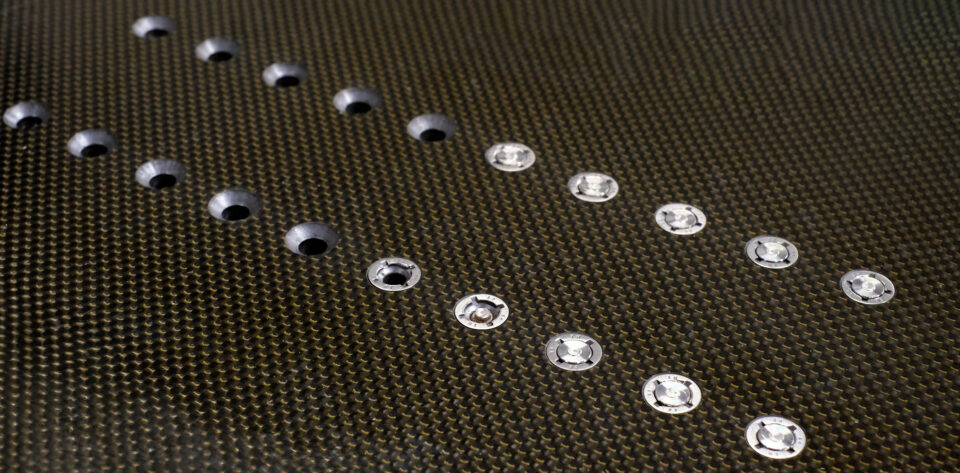

Traditionally, Composi-Loks® are removed using standard methods such as drilling or grinding. Because Composi-Loks® have a hardened stem through the center of the shank, it is easy for the drill to walk off into the recesses of the cruciform. To mitigate this, technicians usually resort to using a die or pencil grinder to shave the stem down before drilling. These methods can be time-consuming, labor-intensive, and pose significant risks of damaging surrounding structures. Moreover, they can generate debris or foreign object debris (FOD), impacting safety and reliability.

Using E-Drill to remove Composi-Loks:

Composi-Loks®, like other Blind-Bolts, deviate from standard nominal diameters and therefore require a larger electrode for removal. Typically, a PLUS size electrode is recommended for removing these fasteners, as -PLUS electrodes are designed to fit between the nominal diameter (-0) and the first oversize (-X). For example, to remove a standard 5/32″ flush-installed Composi-Lok® such as the MBF2112-5, you would typically use a 05-PLUS electrode (EDK0205-PLUS). These specialized electrodes and other Composi-Lok® removal kits such as the mechanical locator kit are available for specific applications and can be ordered from Perfect Point.

The mechanical locator integrates seamlessly into the existing vacuum locator tooling, securely locking into place using mechanical features such as the cruciform recess in the head of the Composi-Lok®. This innovation eliminates the reliance on eyesight-driven locating techniques, ensuring a mechanically concentric location over the fastener head for a precise cut every time.

Utilizing the E-Drill for Composi-Lok® removal offers several distinct advantages over traditional methods. E-Drill’s precision and efficiency significantly reduce the risk of damage to surrounding structures and minimize debris generation. Its non-contact technology provides a safer and more reliable solution for fastener removal in aerospace applications, ensuring minimal disruption while maintaining structural integrity.

Composi-Lok® Part Numbers:

| Part Number | Material | Head Style |

|---|---|---|

| MBF2010 | Titanium | Protruding |

| MBF2011 | Titanium | Hex |

| MBF2012 | Titanium | Flush 100°, Tension |

| MBF2013 | Titanium | Flush 130°, Shear |

| MBF2110 | Titanium | Protruding |

| MBF2111 | Titanium | Hex |

| MBF2112 | Titanium | Flush 100°, Tension |

| MBF2113 | Titanium | Flush 130°, Shear |

| MBF2120 | CRES | Protruding |

| MBF2121 | CRES | Hex |

| MBF2122 | CRES | Flush 100°, Tension |

| MBF2123 | CRES | Flush 130°, Shear |

| MBF2130 | CRES | Protruding |

| MBF2132 | CRES | Flush 100° Tension |

| MBF2133 | CRES | Flush 130°, Shear |

| MBF2134 | CRES | Flush 100°, Reduced Shear |

| MBF2140 | Titanium | Protruding |

| MBF2141 | Titanium | Hex |

| MBF2142 | Titanium | Flush 100°, Tension |

| MBF2143 | Titanium | Flush 130°, Shear |

| MBF2310 | Titanium | Protruding, Low Profile |

| MBF2312 | Titanium | Flush 100°, Tension |

| MBF2313 | Titanium | Flush 130°, Shear |

| MBF2315 | Titanium | Flush 130°, Shear |

| MBF2322 | CRES | Flush 100°, Tension |

| MBF3003 | Titanium | Protruding |

| MBF3004 | Titanium | Hex |

| MBF3005 | Titanium | Flush 100°, Tension |

| MBF3006 | Titanium | Flush 130°, Shear |

| MBF3008 | CRES | Protruding |

| MBF3010 | CRES | Flush 100°, Tension |

| MBF3011 | CRES | Flush 130°, Shear |

| MBF3012 | Titanium | Protruding |

| MBF3013 | Titanium | Flush 130°, Shear |

| MBF3015 | CRES | Protruding |

Visu-Lok®, Composi-Lok®, Radial-Lok®, OSI-Bolt®, Wedgelock® are Registered Trademarks of Monogram Aerospace Fasteners, Inc. Monogram Aerospace Fasteners is a TriMas Company. Perfect Point EDM, Corp. has no affiliation with Monogram Aerospace Fasteners, Inc. or Tri-Mas.