E-Drill Troubleshooting

Delve into our curriculum on E-Drill Troubleshooting. For the full E-Drill Training, Maintenance and Troubleshooting catalog, visit the full E-Drill Academy Page.

Filter E-Drill Academy Videos

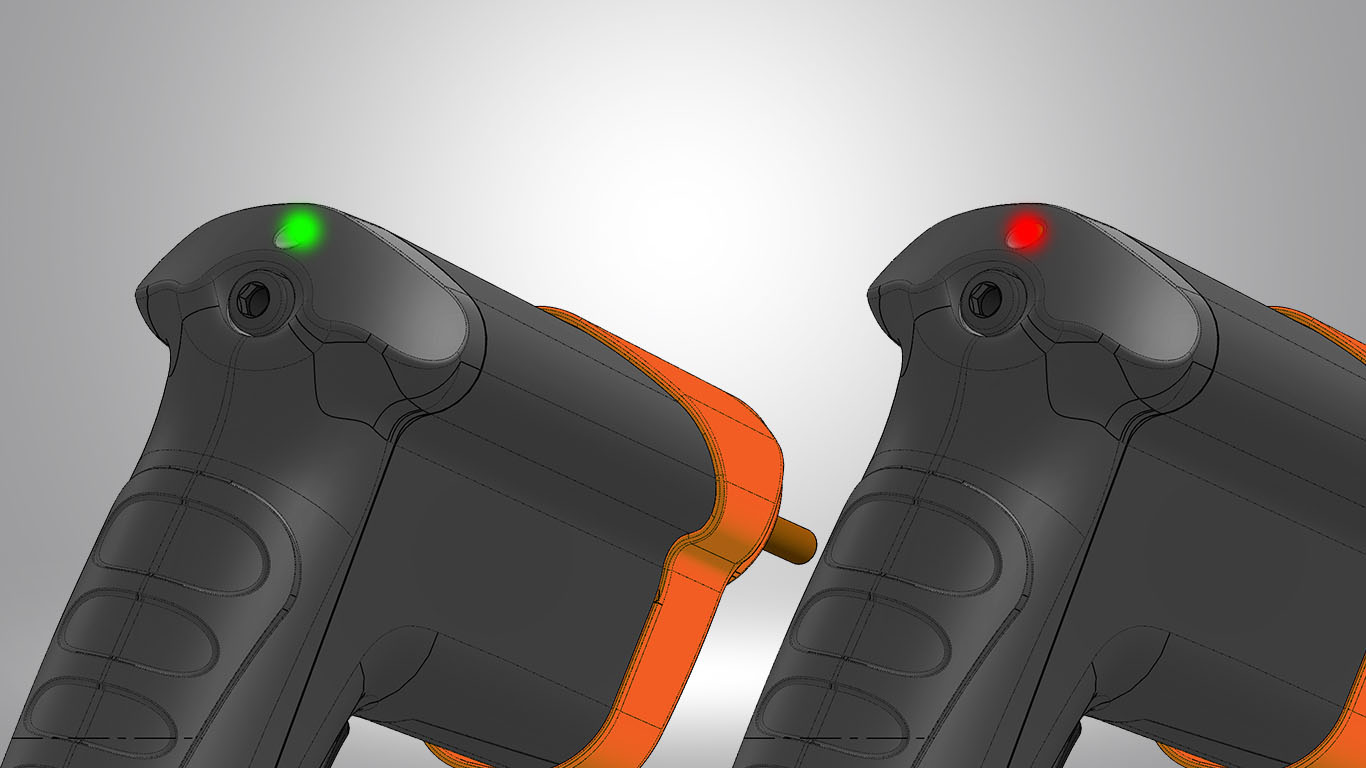

E-Drill Status Lights

E-Drill 1.0, E-Drill 2.0The Status Light communicates various conditions during operation. The status light effects are as f...

E-Drill 2.0 Daily Checklist

E-Drill 2.0Please follow this checklist to maximize the performance and reliability of your E-Drill System....

Troubleshooting Tables

E-Drill 1.0, E-Drill 2.0Common maintenance issues encountered and their solutions. In the event of issues, it is recommended...

System Bleeding and Charging Procedure

E-Drill 2.0Bleeding and charging are sometimes required to assure there is no trapped air in the DI system....

Checking Vacuum and pressure

E-Drill 2.0The system is provided with Vacuum and Pressure gauges to check the performance of the Dielectric wa...

Changing/Adjusting the Ground Pin

E-Drill 1.0How to change and adjust the ground pin of the Center Ground(CG) handtool for an E-Drill 1.0 Machine...

Bleed and Fill (Troubleshooting)

E-Drill 1.0Performing a bleed and fill. This is performed as a troubleshooting step (if you hear a screeching s...

Changing the Filter – E-Drill 1.0

E-Drill 1.0This maintenance needs to be performed every 5500 cuts. You will see a 500 cut countdown appear at...