FASTENER REMOVAL HAS

NEVER BEEN EASIER

The E-Drill can achieve up to a 20x reduction in fastener removal times, dramatically increasing aircraft turnaround times and reducing downtime.

The computer-controlled process paired with enhanced location tooling, ensure minimal risk of airframe damage during the fastener removal process.

The closed-loop water filtration system of the E-Drill continually flushes out and filters debris from the cut process. This eliminates drill shavings and other cut debris found when using a twist-drill.

The E-Drill is a revolutionary handheld device that leverages patented electro-discharge machining (EDM) technology to redefine the way fasteners are removed in aerospace maintenance. Its precision, speed, and safety features make it a game-changer in the industry.

HOW E-DRILL WORKS

1. Locate

The key to the E-Drill process is LOCATION, it’s why our damage rate is less than 1%. Precise alignment of the E-Drill over fasteners is crucial for effective removal and minimizing damage to aircraft structures.

For flush-installed fasteners, vacuum tooling is employed to stabilize the E-Drill. A magnifying “bombsight” with interchangeable aperture rings or a mechanical locking mechanism is placed inside the vacuum locator tool to align to the center of the fastener. Once the location is set, the locator tooling is held in place using vacuum, and the E-Drill hand tool is then inserted into the locator tool to make the cut.

For protruding head fasteners, Button Head Locators (BHLs) with interchangeable metal bushings are used to ensure concentric positioning, guiding the E-Drill for accurate cuts. These bushings match the fastener’s diameter and secure the E-Drill’s alignment, ensuring cutting precision.

Button Head

For raised/protruding head fasteners, E-Drill locks over the center mechanically using machined bushings. Click to see how it works

More Button Head InfoFlush Head

For flush fasteners, E-Drill uses vacuum tooling to locate and lock into place. Click for more info on how it works

More Flush Head Info2. Cut

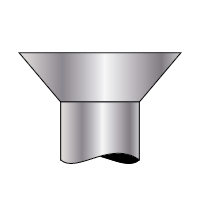

Once the E-Drill is positioned over the fastener, its patented handheld electrical discharge machining (EDM) technology quickly and easily removes even the hardest fasteners. In mere seconds, a precision-sized electrode cuts a circular groove of material from the fastener head, leaving a thin fracture point between the head and stem. The exact sizing of the electrode, combined with precision depth control, greatly reduces the risk of airframe damage compared to conventional removal methods.

During the cutting process, a closed-loop fluid system with filtered water flushes the area and removes debris. This aggressive flushing prevents heat transfer to the surrounding area. The forceless cut process significantly lowers the risk of airframe damage and repetitive motion injury to the operator. It is adaptable to flush head, protruding head, collar-side, and many other custom applications.

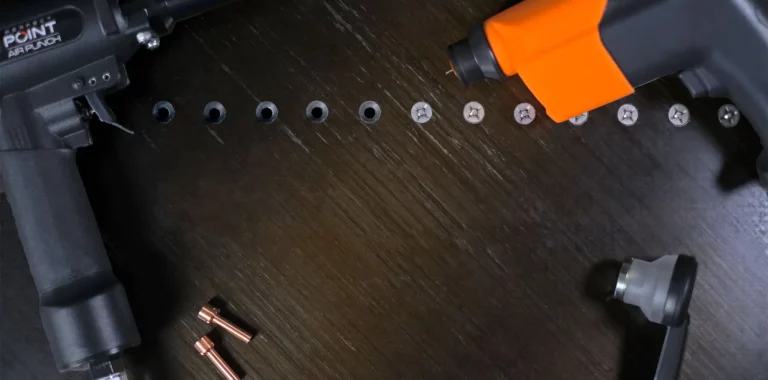

3. Punch

The Single Shot Air Punch is designed to remove the flange heads from fasteners that have been cut using the E-Drill.

The nose adapter engages in the E-Drill cut groove to prevent misalignment. The Air Punch uses a single strike to the fastener pin and no other part of the structure to provide a better, faster, and safer removal.

The Air Punch reduces potential damage to the structure, and significantly reduces the chance of impact injury and repetitive motion injury to the operator.

schedule an on-site demo