Perfect Point Capabilities

What We Do:

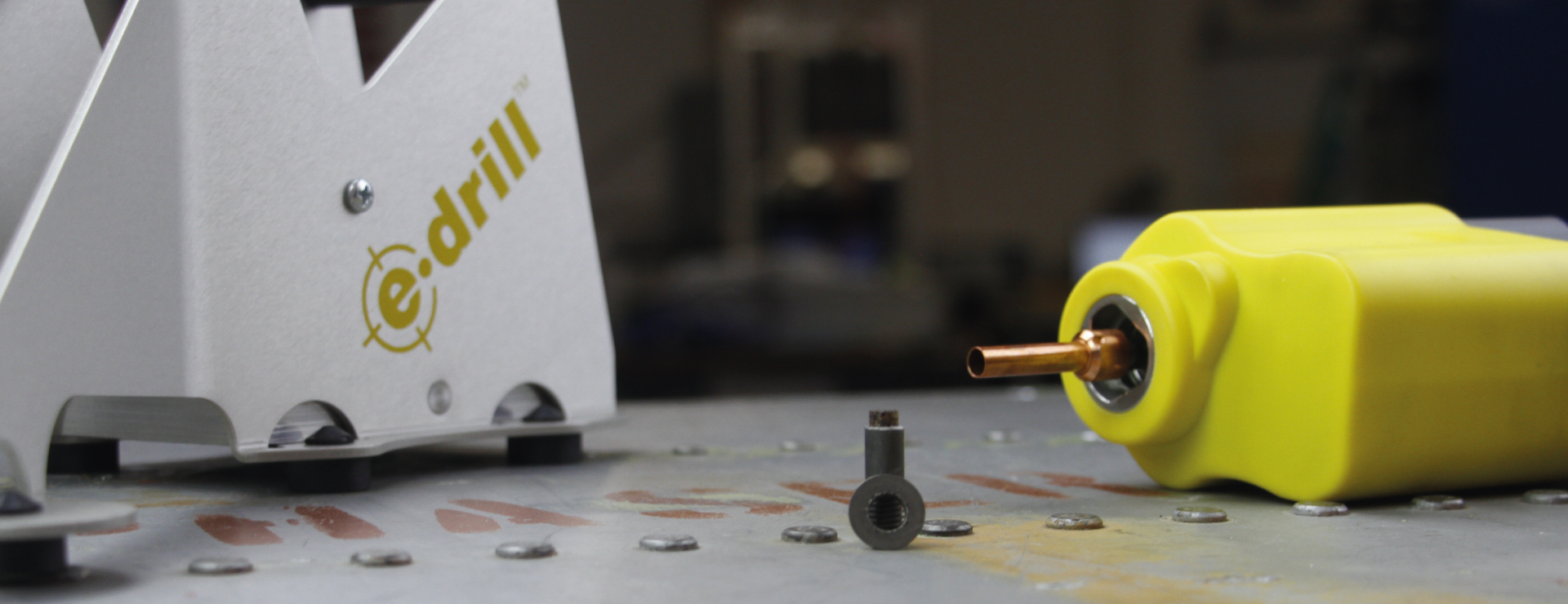

Perfect Point’s Fastener Separation Technology (FST) is an entirely new application of Electro-Discharge Machining (EDM), developed and patented by Perfect Point EDM Corp. E-Drill® and S-Blaster® were specifically designed to yield exponential productivity improvements in the field of Aerospace Fastener removal. E-Drill FST’s patented ElectroDischarge Machining Process separates hard-metal fasteners in seconds.

E-Drill FST utilizes a tubular electrode to separate fastener heads or collars from a fastener’s shank. Regardless of the metallurgy of the fastener, E-Drill FST can cut/separate all fastener types and sizes, including: Solid, Cherry, Huck, HiLok, Composi-Lok, and Taper-Lock, from diameters 3/32-7/16”. Titanium fasteners are separated in 8-10 seconds, versus a typical time of 5-7 minutes for traditional drilling and/or collar separation techniques.

Perfect Point is changing the way structural maintenance is performed in the 21st Century, by providing a Faster, Safer, and More Accurate method of removing “Hard-Metal” Fasteners in airframe structures and engines. E-Drill FST enables Exponential Productivity Improvements, drives firstpass Quality, Reduces the Cost of Consumables, and Protects Workers.

Key Differentiation:

The PPEDM E-Drill is the only tool using EDM technology in a hand-held device. We have 6 awarded patents that protect our technology and limit the development and use of EDM in a handheld device by other potential competitors. In the Aerospace market, we are the only company that is focused on the removal of fasteners.

| Technical Capabilities | E-drill Value Proposition |

|---|---|

|

|